bottling technology, beer, bottle, juice, wine

Round filler TA10 / TA14 / TA16

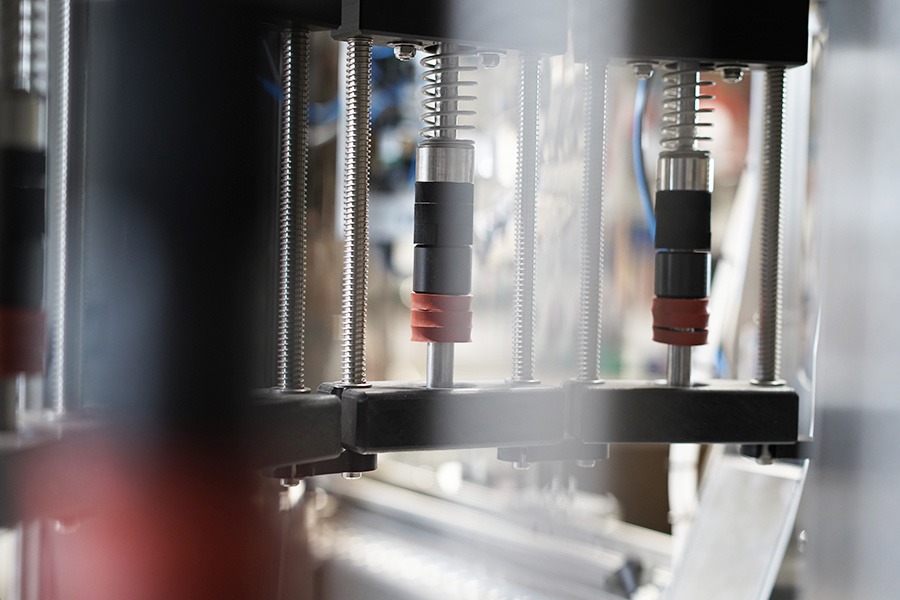

Drop pressure rotary filler with 10/14/16 filling stations

Electric tank height adjustment - easy adjustment of bottle and filling height

Electronically adjustable filling capacity

variant for hot juices available

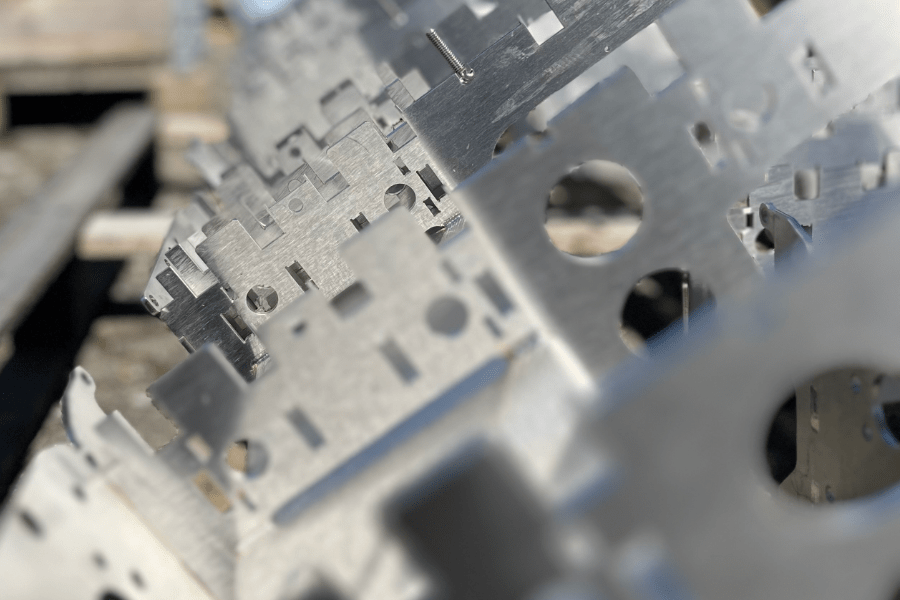

Easy changing of the carry-on tester for different bottle diameters

CIP unit for dry cleaning available

Dampable

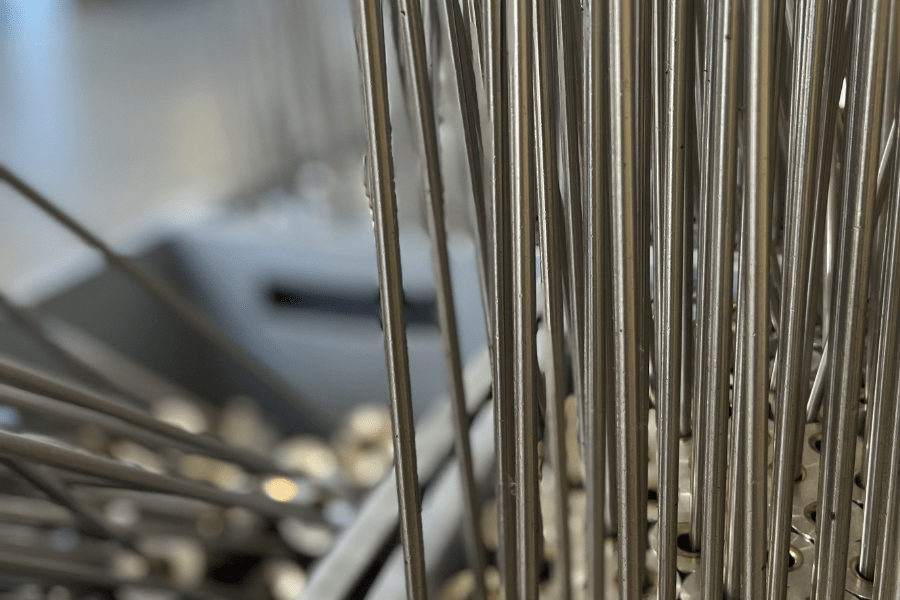

Made entirely of stainless steel

With our capper TV2000 or TV2000TWIN you have a suitable addition

Standard versions

TA10

Round filler with 10 filling stations

TA14

Round filler with 14 filling stations

TA16

Round filler with 16 filling stations

Technical data

Electrical connection

230V AC

Dimensions (L x W x H) [mm]

1200 x 900 x 2000

Weight [kg]

210 / 250 / 250

Filling valves

10 / 14 / 16

Container volume

90 / 180 / 180

Capacity up to [bottles/h]

1600 / 2000 / 2200

Bottle height [mm] max.

180-380

Bottle diameter [mm]

55-90

Optional extras

Infeed/outfeed conveyor belt

2250mm long, other lengths on request

Fill level monitoring

with 2-point control

CIP unit

for dry cleaning

CO2 in the filling tank

CO2 overlay in the filling tank

Hot filling

with temperature sensor and digital temperature display

Wheels

makes our bottler mobile

Transport and lifting frame

For easy positioning of the machine with a forklift/lift truck

CO2 overlay with or without level control

CO2 injection, optionally with suction to the desired level

Congestion sensors

for easy integration into existing production lines