Filling and capping technology

Your needs, our passion!

Get to know KTM-Troxler's innovative solutions for filling and capping technology as well as our red wine technology.

Depalletizer

- Height platform for depalletizing bottle pallets (TDP)

Feeding table

- Feeding table round Ø1000, driven (INTD1000)

- Smart task crossband (INQB)

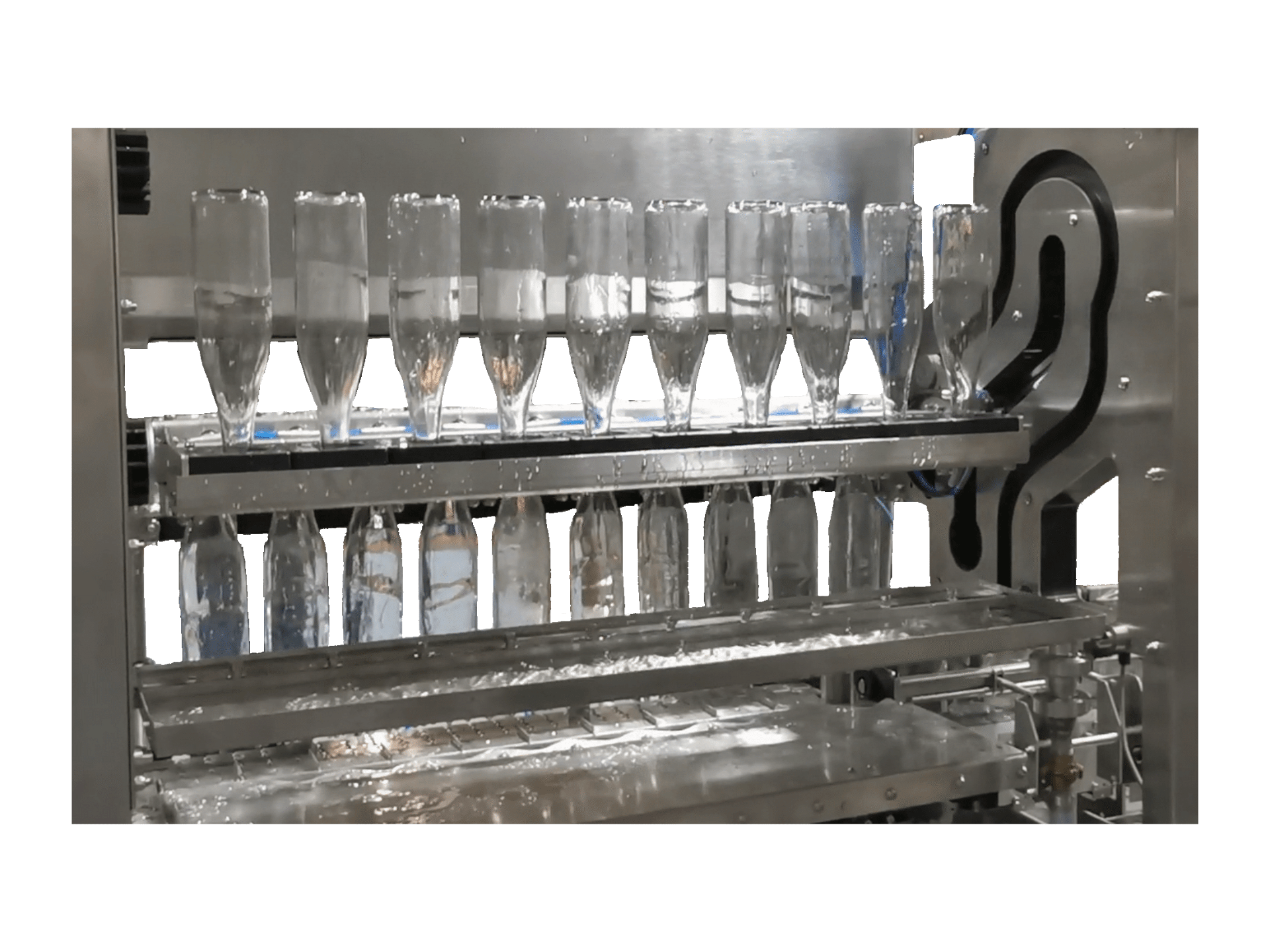

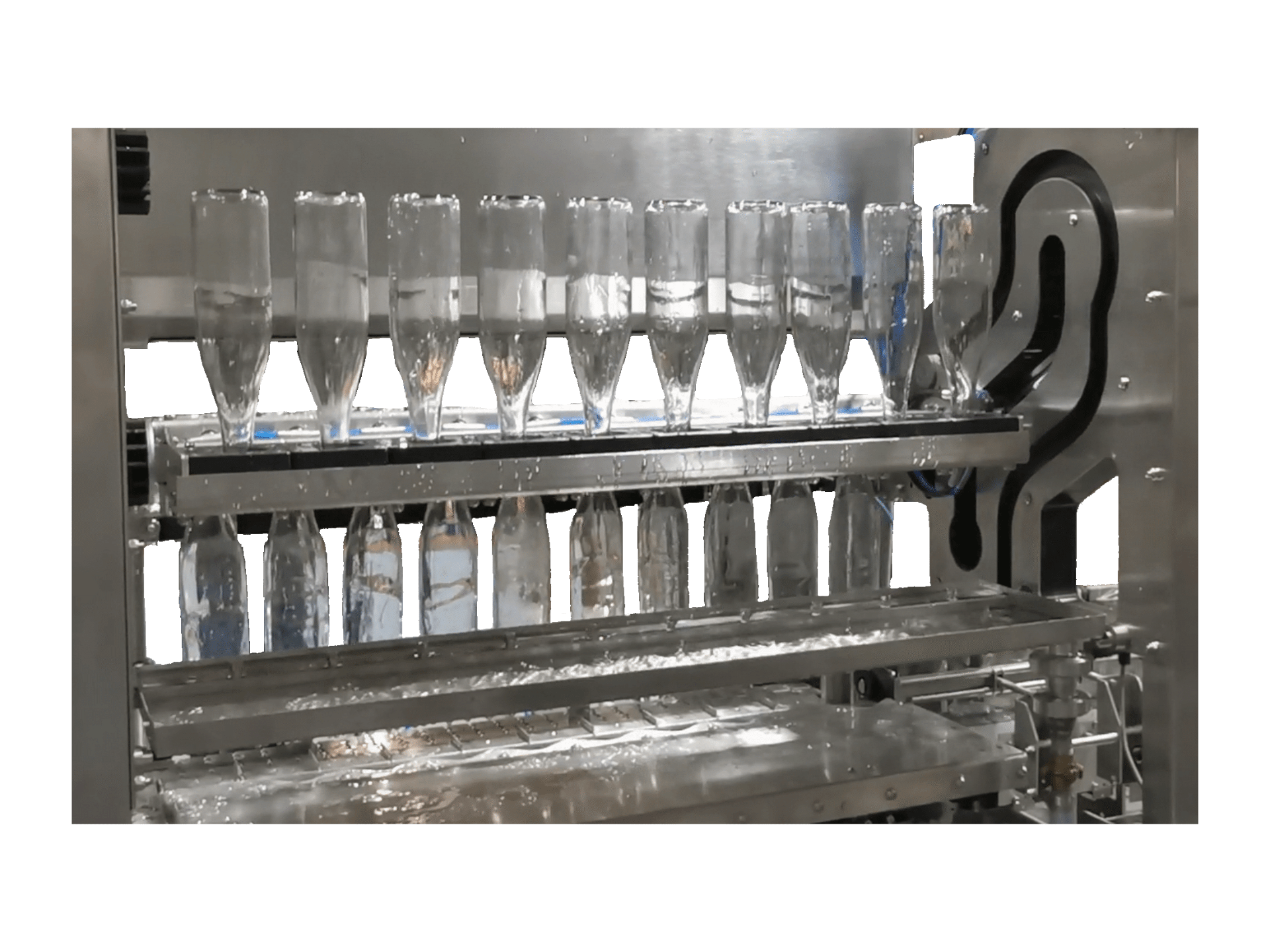

Rinser

- Extension of the linear filler with a single (TR)

- Can rinser tunnel (TRD)

Pre-evacuation

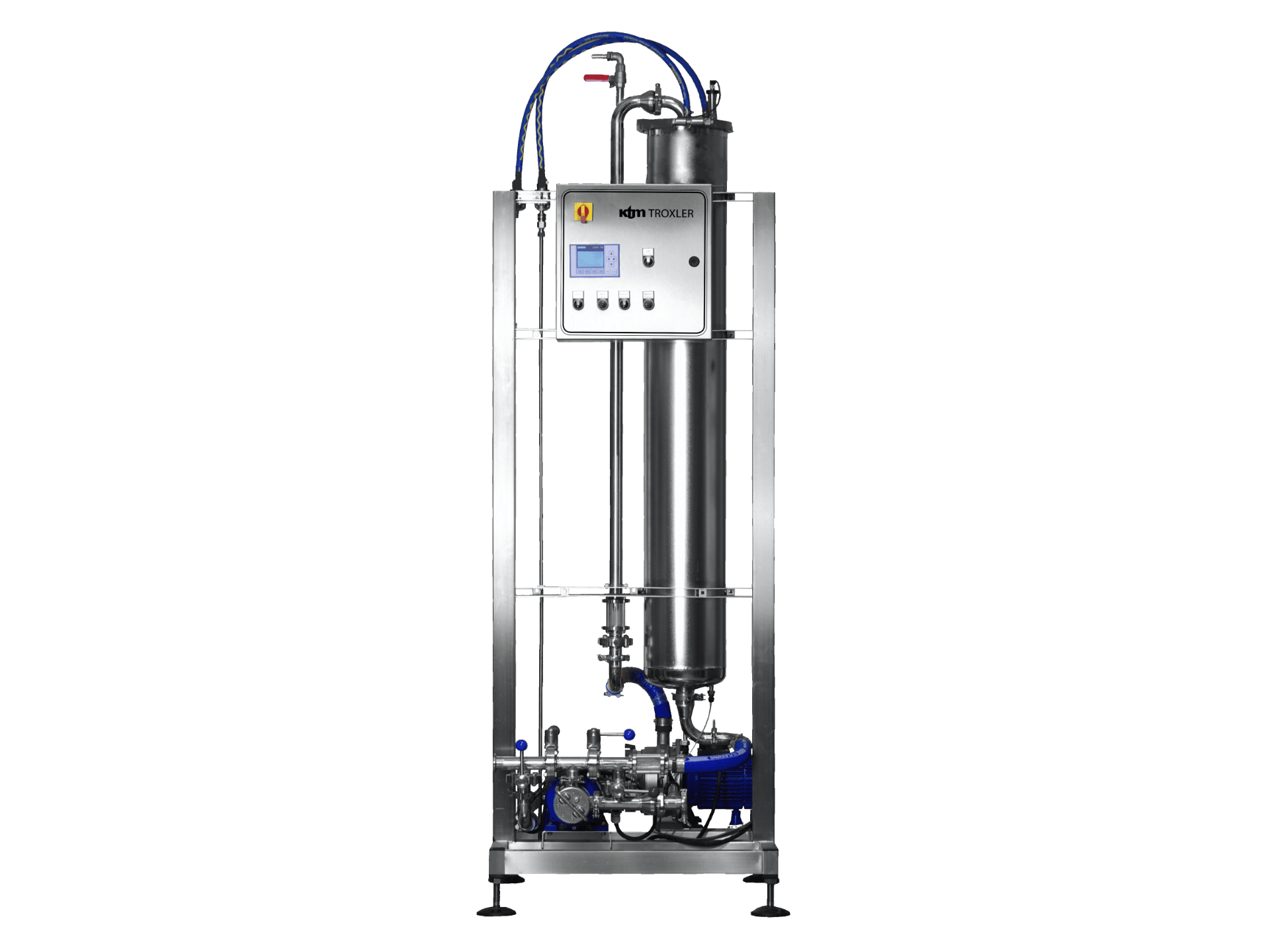

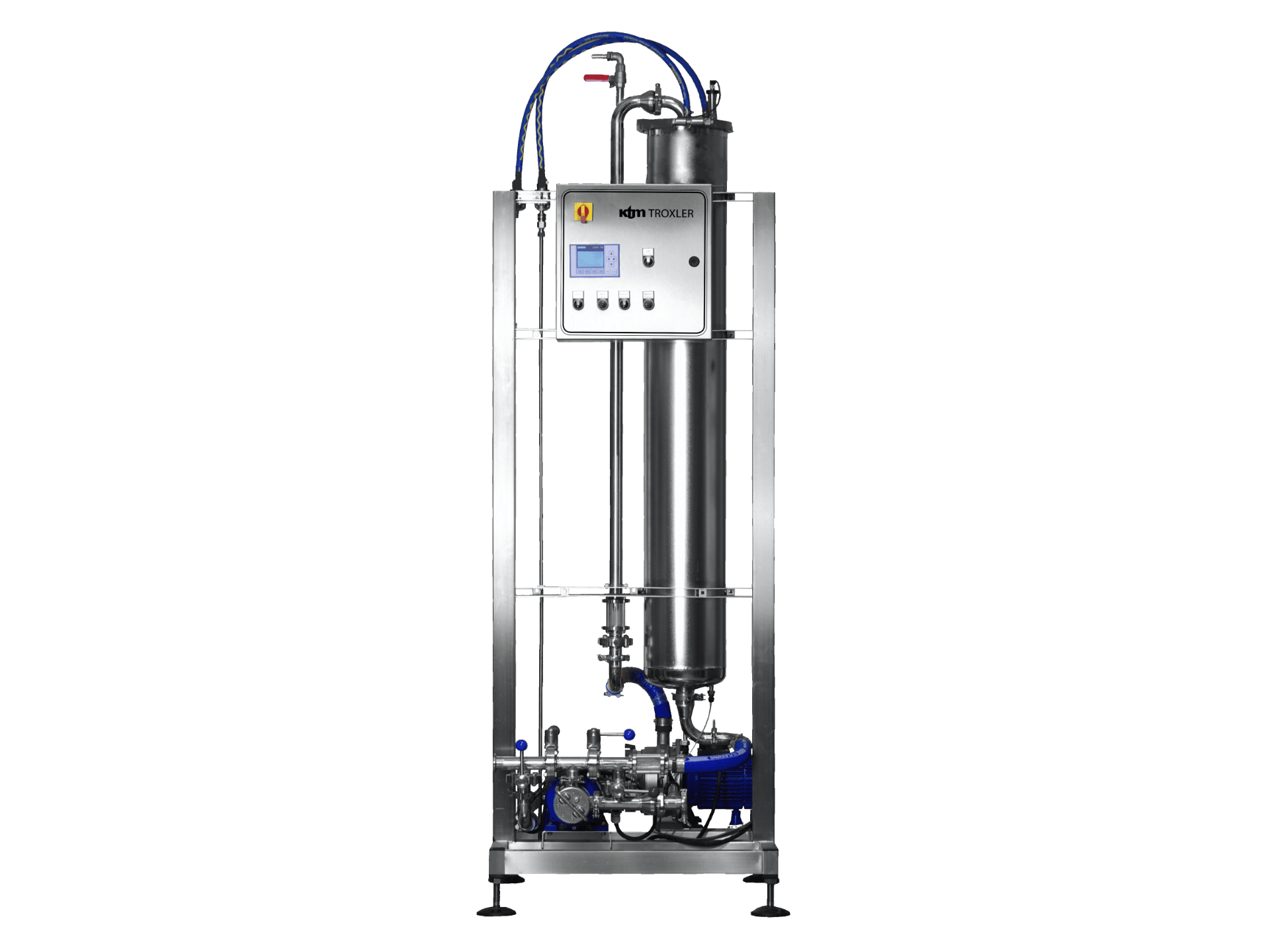

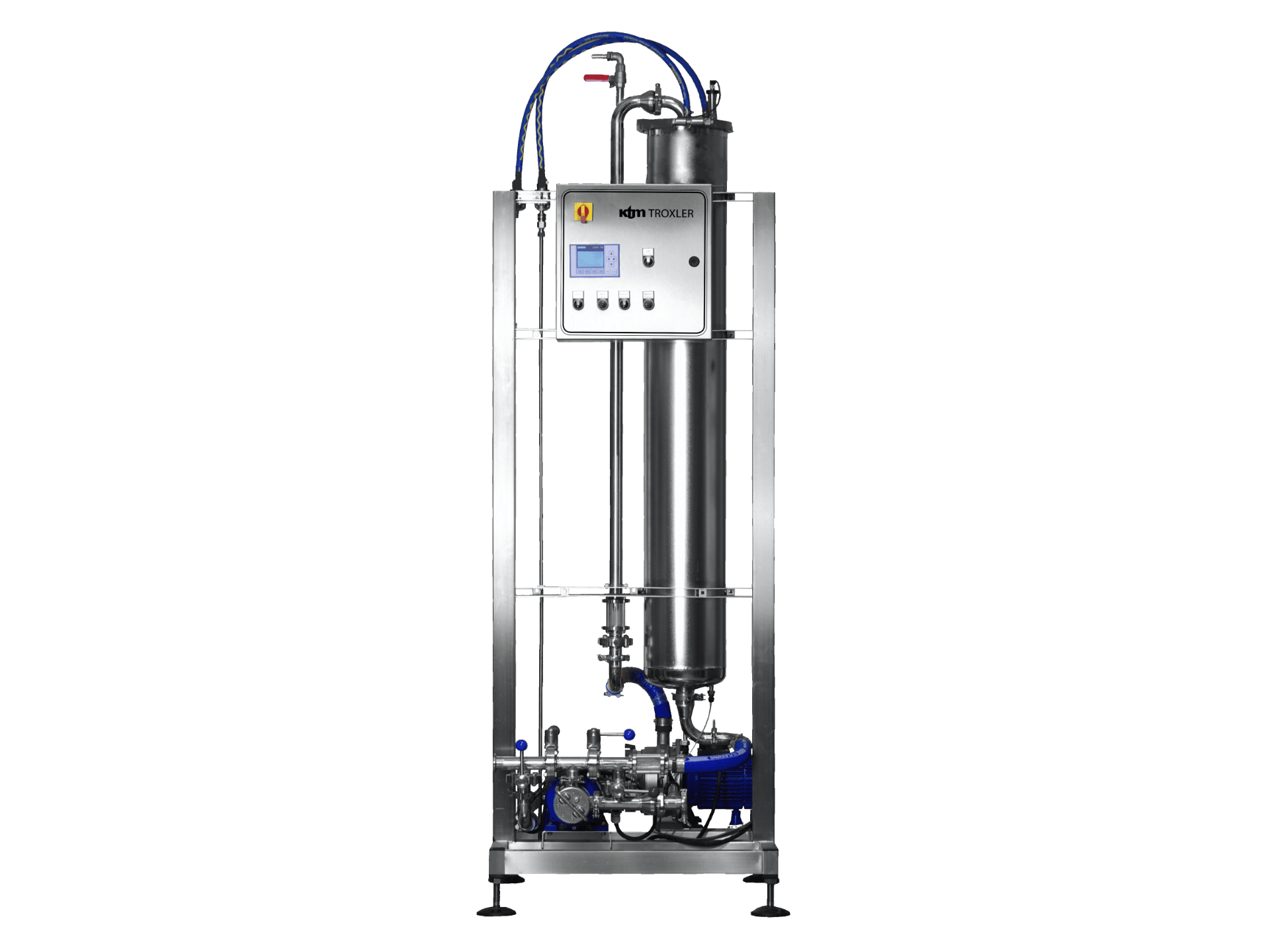

- Vacuum inert gas station (TVI)

- Bottle pre-evacuation (TAL-VAKU)

- CO2-Flushing (CO2-TI)

Carbonization

- Carbonizer (TCA)

Filling

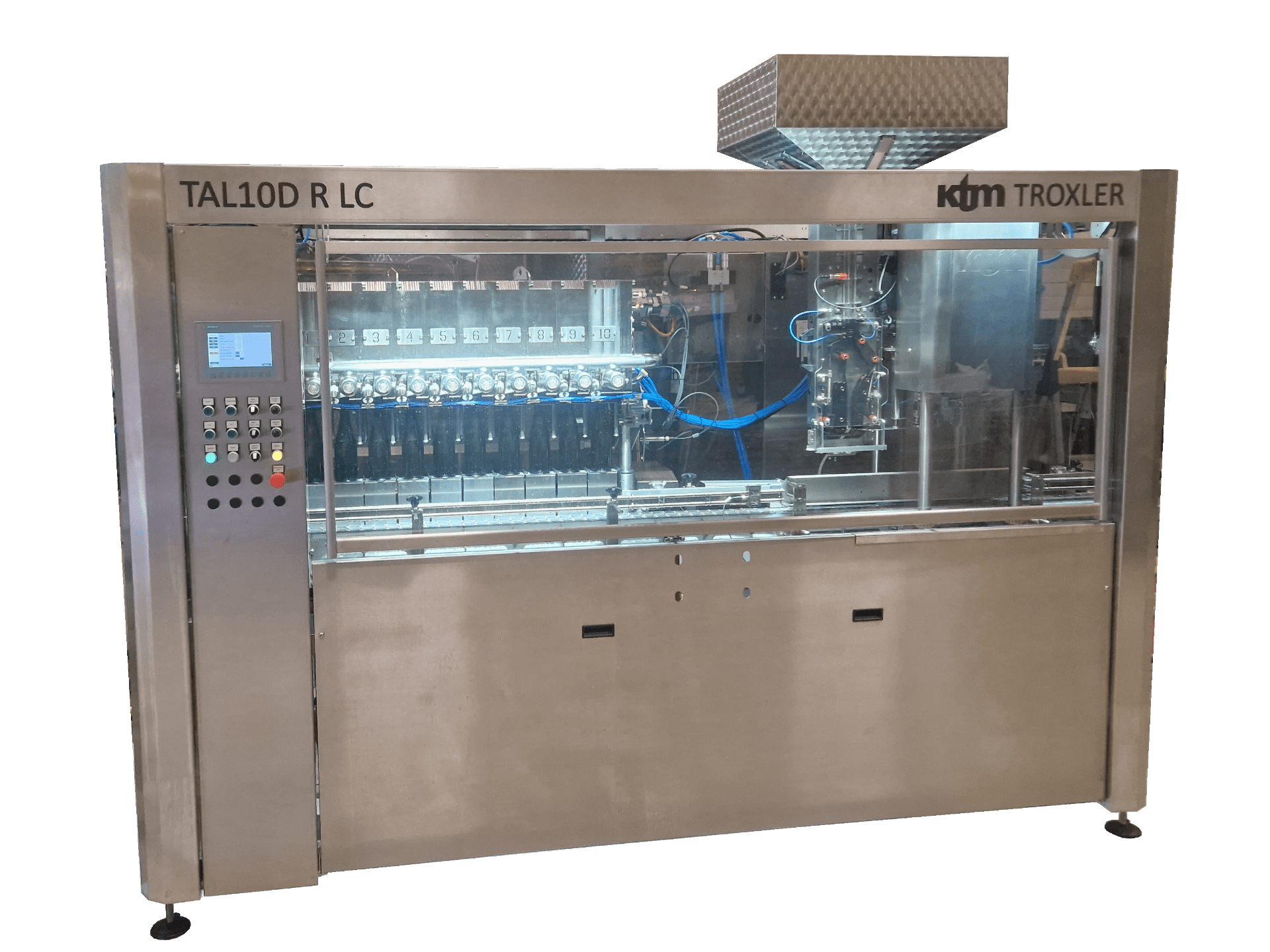

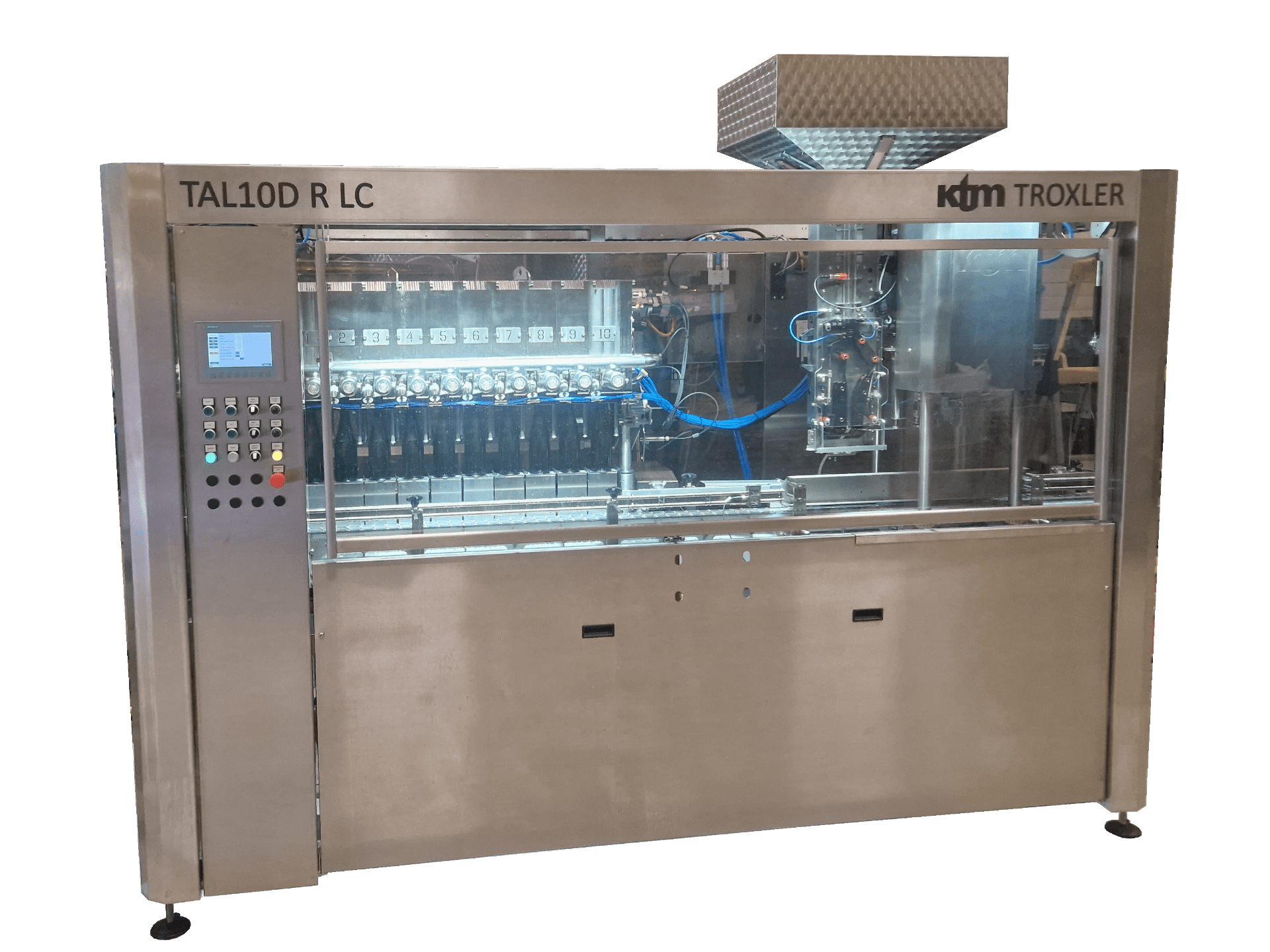

- Linear counter-pressure filling system (TAL-D)

- Linear gravity-feed filling system (TAL-G)

- Waste and sealing machine, fully automatic (TVA)

- Waste and sealing machine, semi-automatic (TA1600)

- Round filler, semi-automatic and fully automatic (TA)

CO2-Level control

- CO2-Overlay and level control (CO2-NR)

Shutter feed

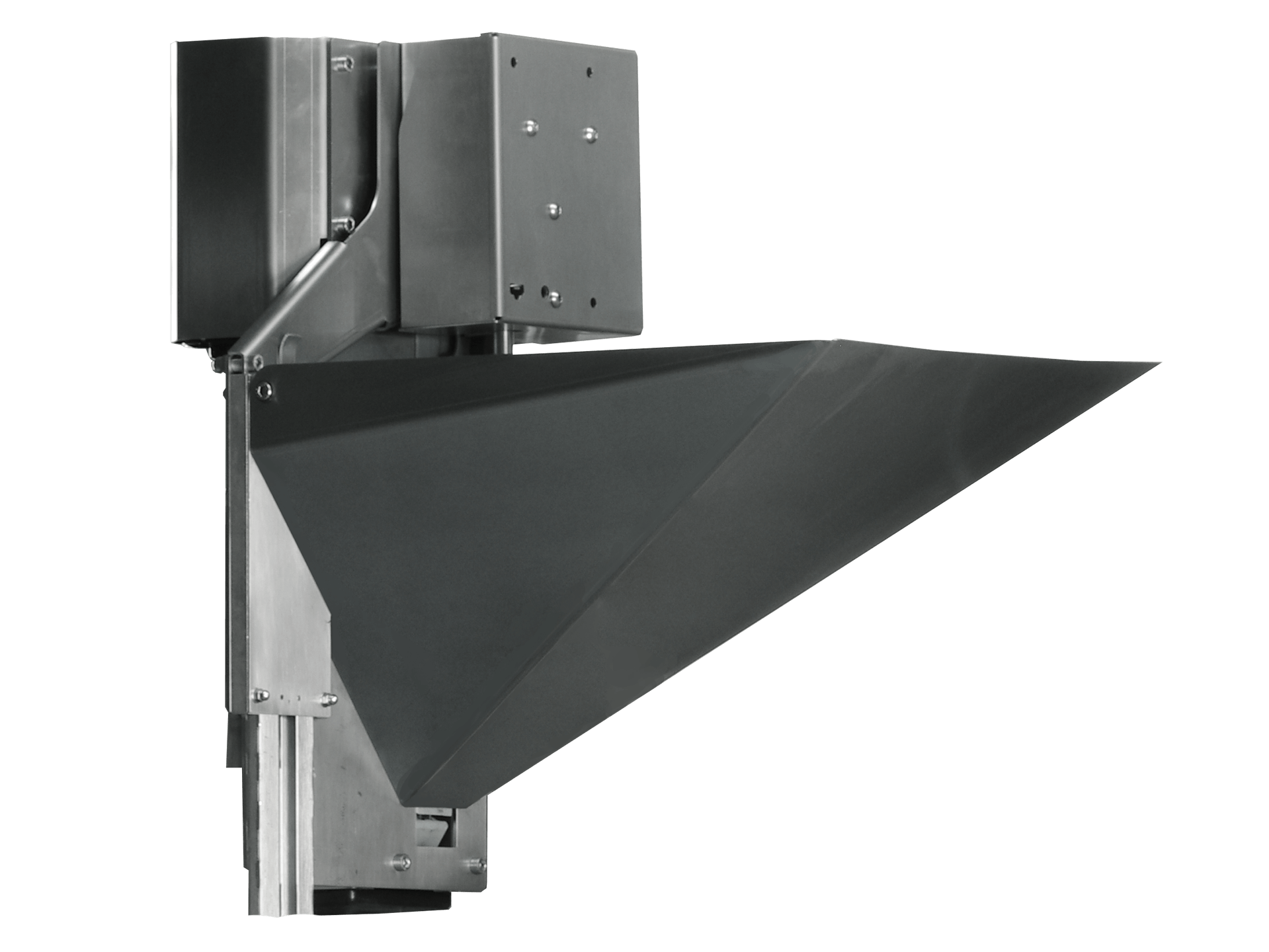

- Sorting applicator for LongCaps (TSL)

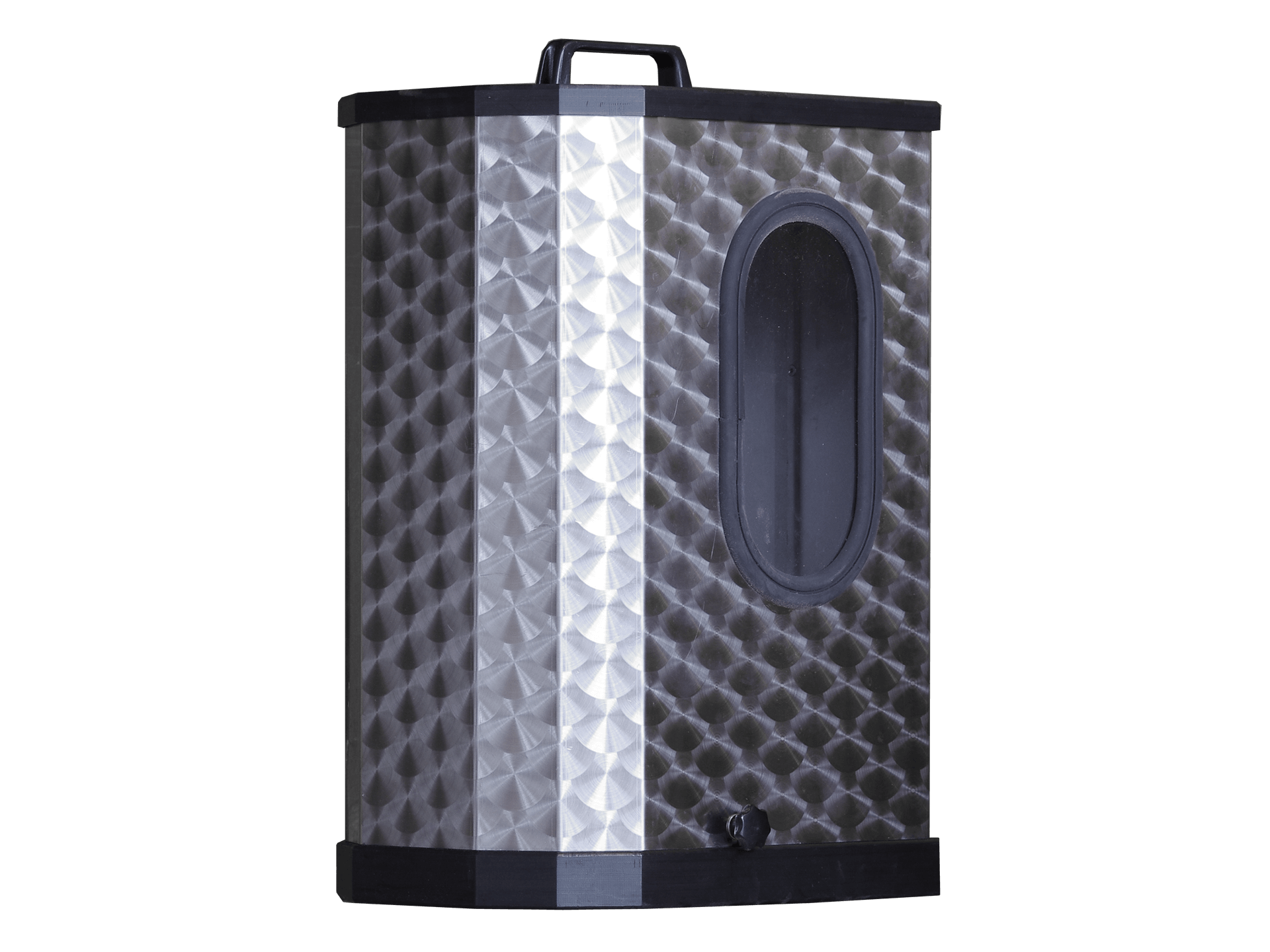

- Sorter for ShortCaps (TSS)

- Sorter for crown corks (TSC)

- Sorter for natural corks (TSK)

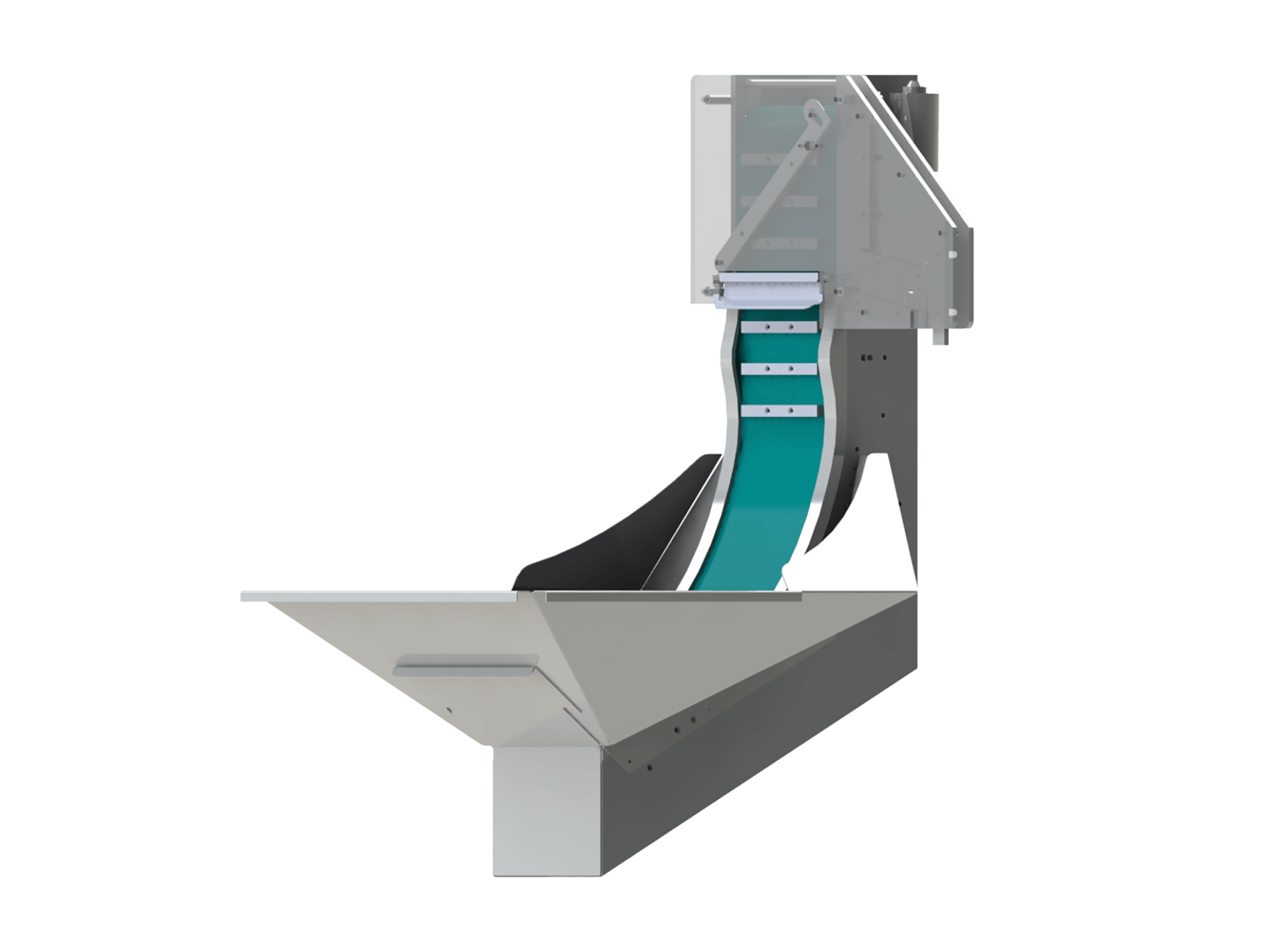

- Sorter as belt version for ShortCaps, special closures, Twist-Off (TSB)

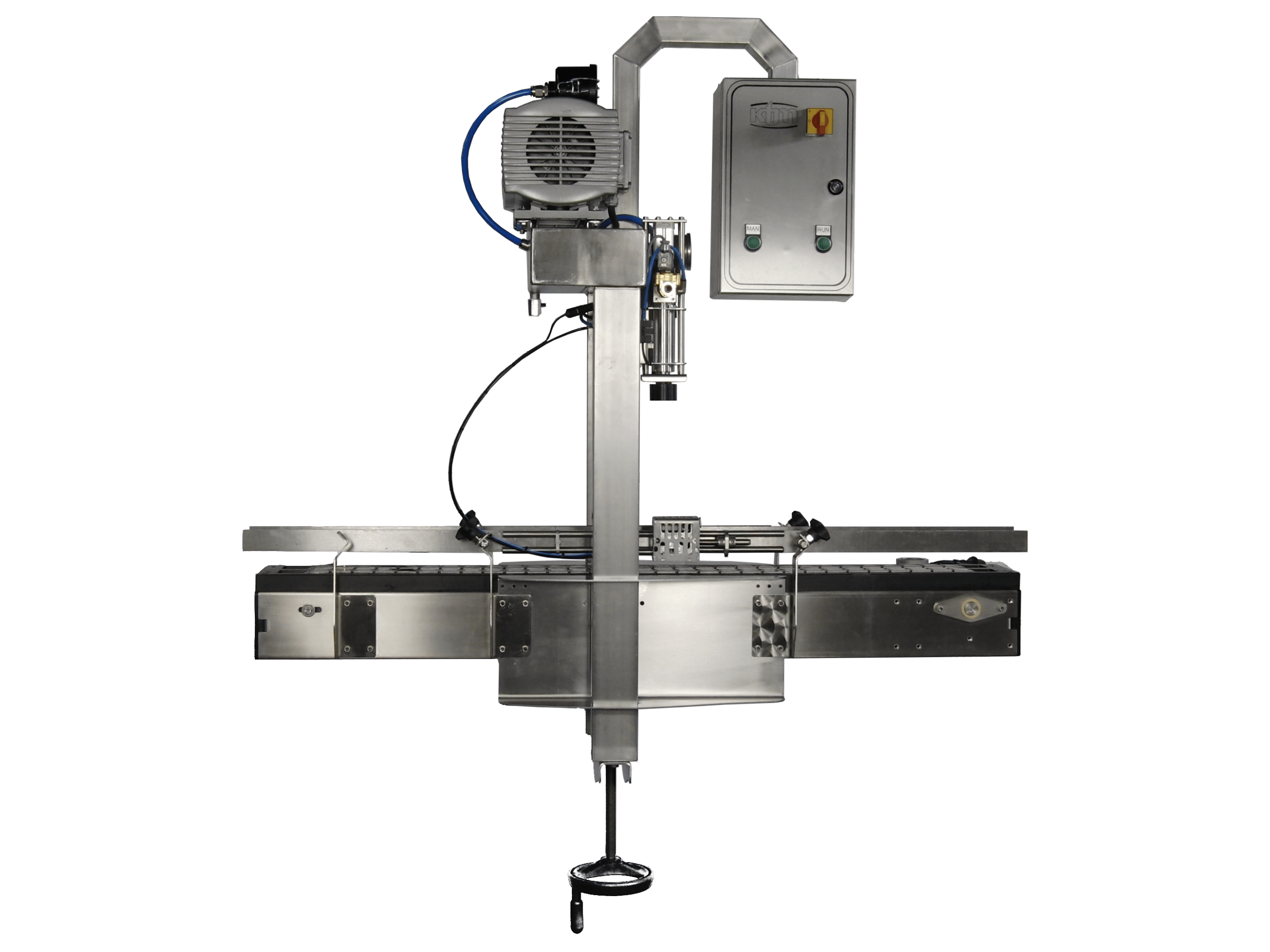

Capper

Design depending on the closure:

- Fully automatic (TV2000, TVTKORK, TVPP)

- Fully automatic with two capping stations (TV2000TWIN)

- Can seamer (TVD)

- Semi-automatic (TV900)

Washer, turner, dryer

- Washing tunnel (TWT)

- Bottle turner (TFW)

- Drying station (TA-DRY)

Collection table

- For capper TV2000 (STTV2000)

- Collecting table round Ø800, Ø1000, driven (STD800/STD1000)

Collection table

- For capper TV2000 (STTV2000)

- Collecting table round Ø800, Ø1000, driven (STD800/STD1000)

Advantages and services

Experts in filling and capping technology. Our filling and capping machines are in use all over the world. We offer compact, sophisticated, customised solutions for your challenges! You can achieve top results with our red wine technology.

Advice

Our comprehensive advice helps us to find the optimum solutions, which we tailor to your needs.

Development

We can adapt existing solutions to your requirements or develop a customised solution for you from scratch.

Production

We have been developing and producing our machines ourselves for three generations. Expect excellent "Made in Germany" quality.

Service

We are there for our customers and provide excellent service - before, during and after the purchase of our products.

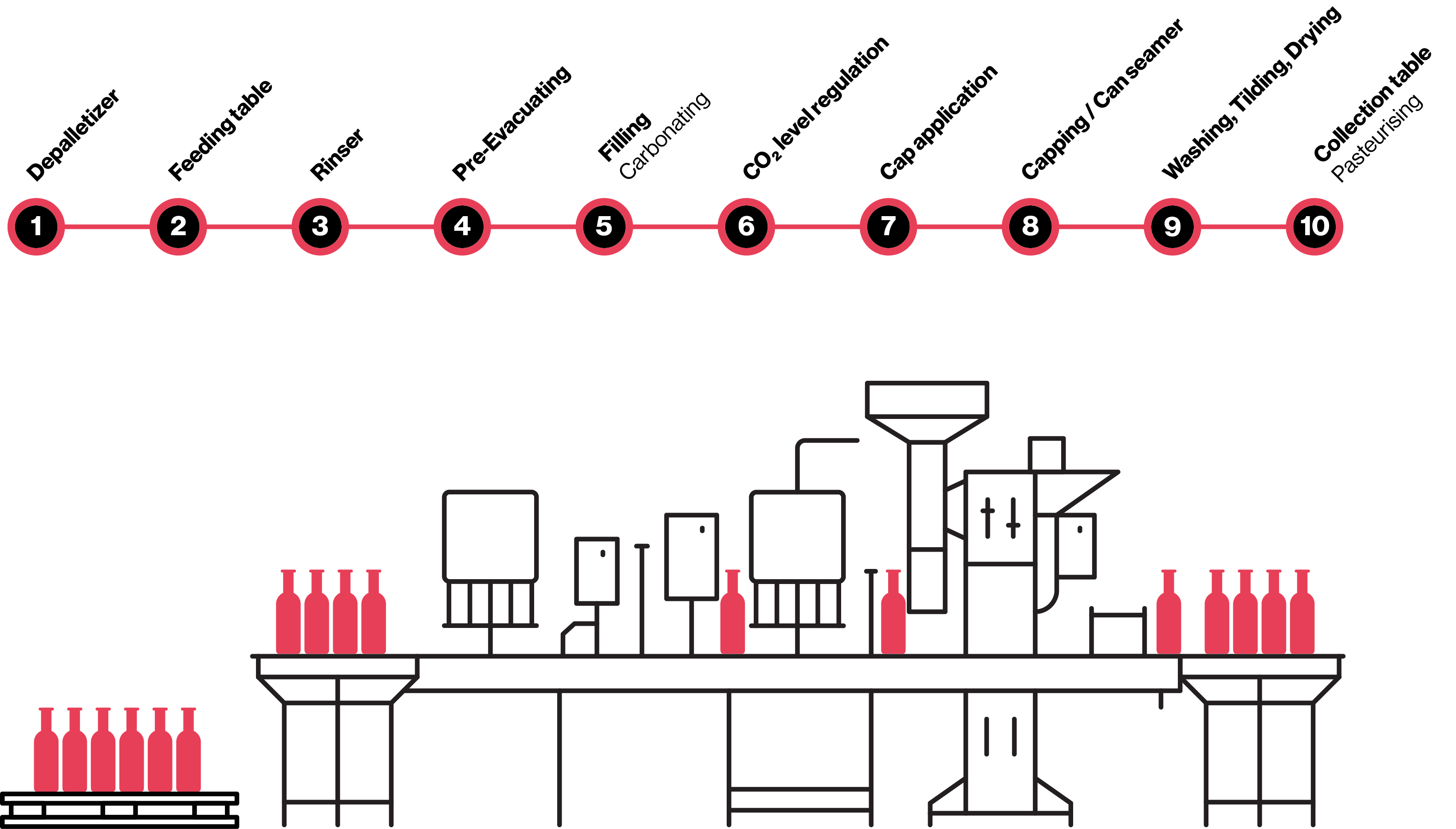

Our products

From depalletizing to capping, we cover the complete process of machine filling. See how we can support you in your process.

- Filling and capping technology 9

- Filling technology 11

- Sealing technology 12

- Sorting technology 5

- Carbonizer 1

- Hot filler 2

- Schwefler 1

- Red wine technique 1

Filling and capping technology

From automated filling to precise capping technology, we offer comprehensive solutions for the entire liquid filling process. Discover how we can optimally support your process.

All products

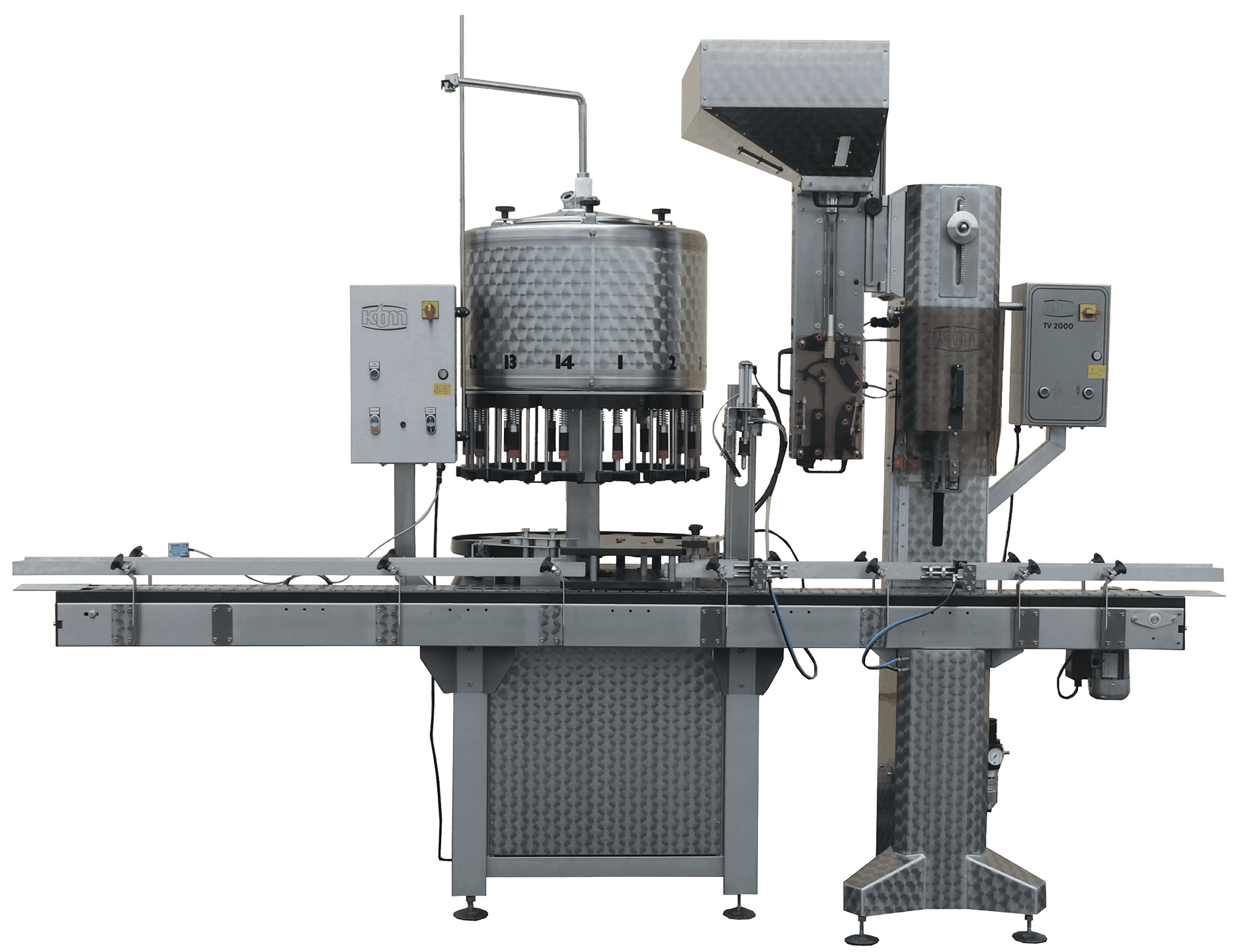

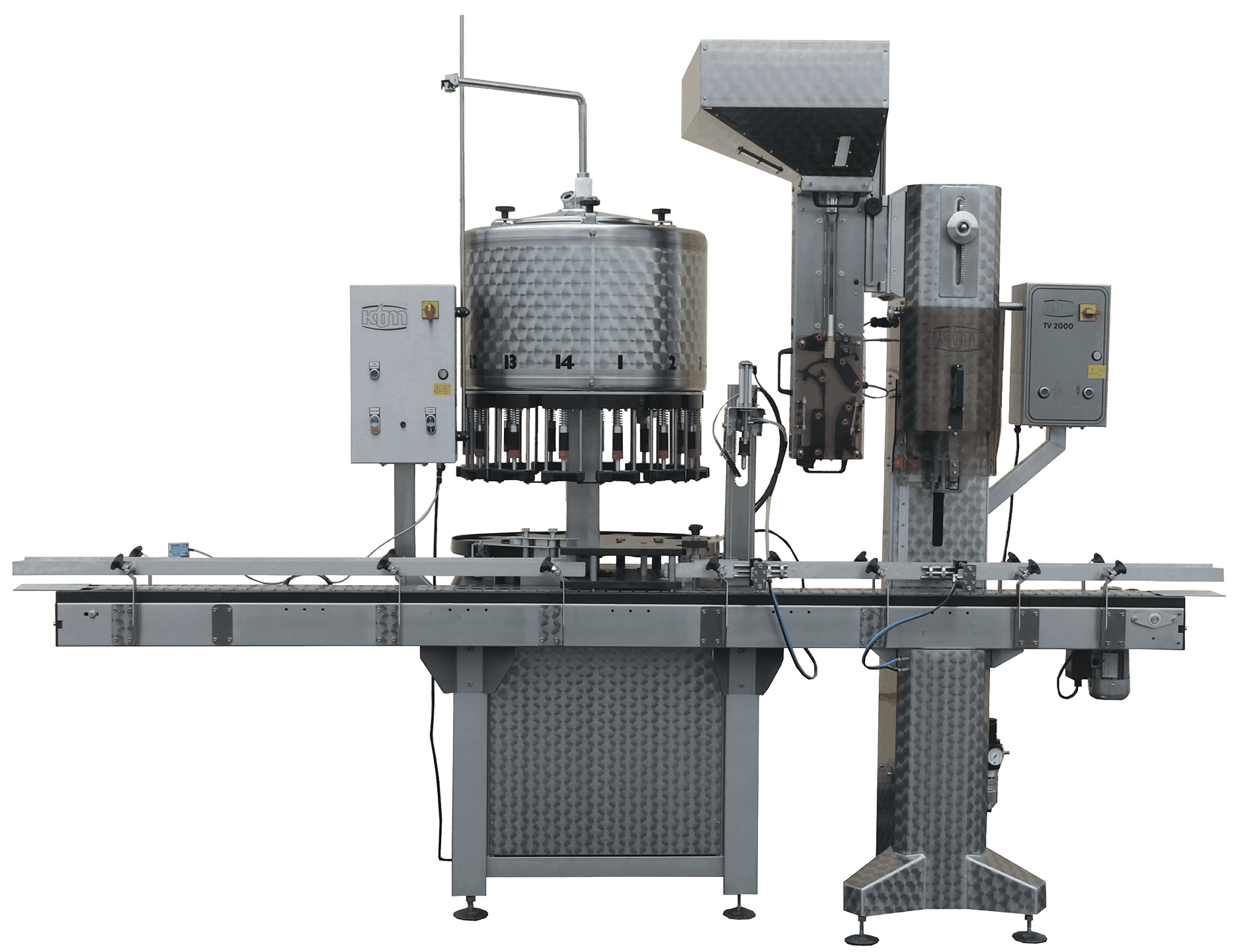

Bottle filling and capping machine TVA

The perfect combination - KTM fillers and cappers for all closure types

See in detail

Capper TVD - It's not just bottles, we can process cans too

With our TVD capper, we can seal cans from 150 ml to 700 ml

See in detail

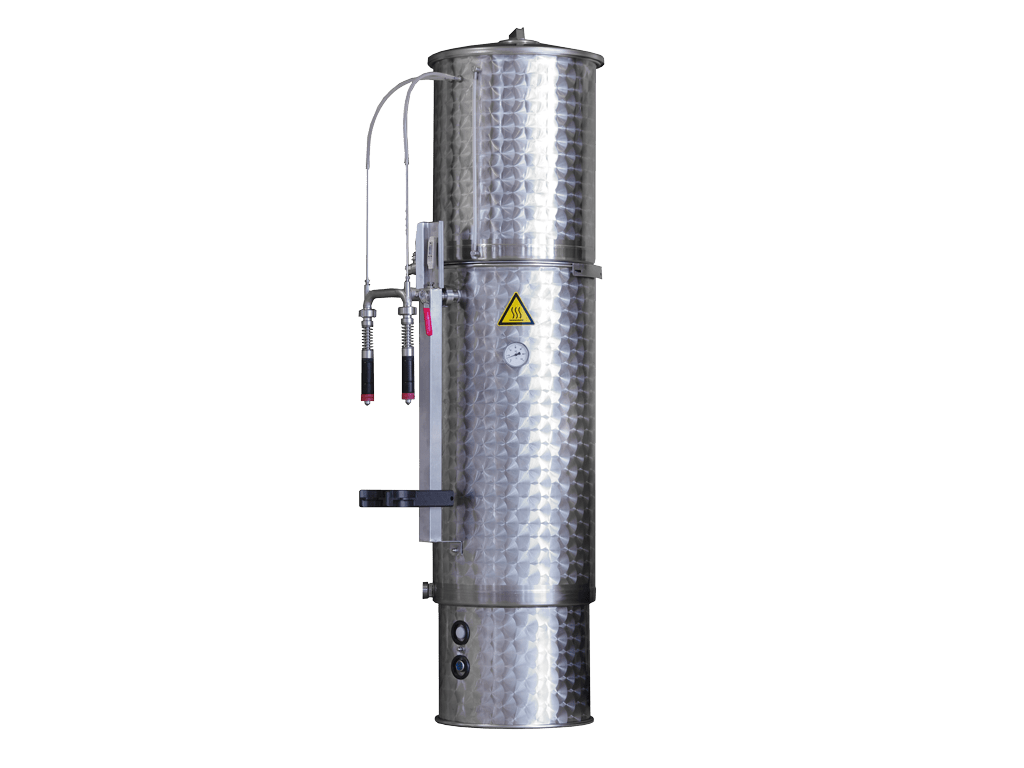

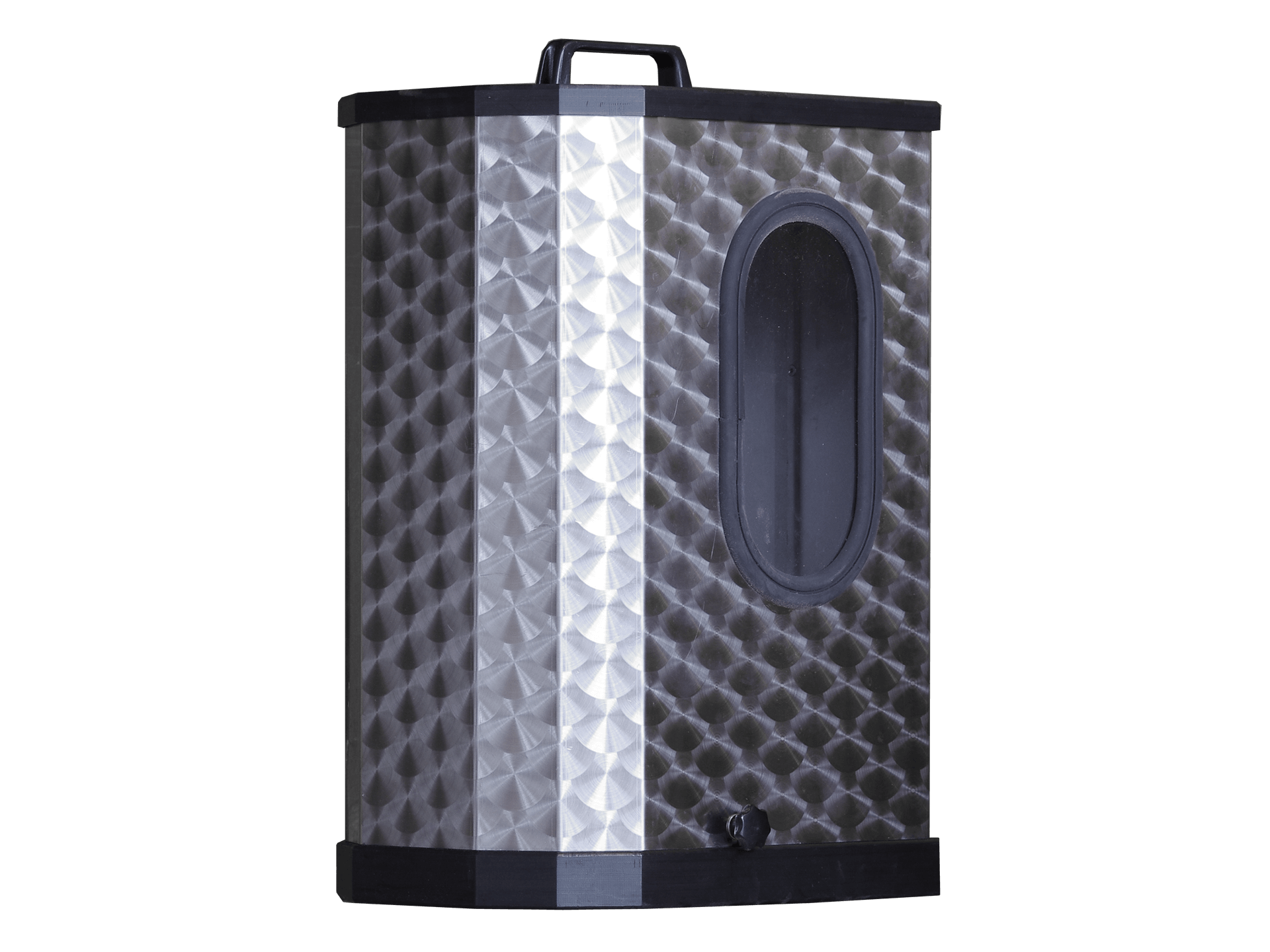

Vacuum inert gas station TVI

For evacuating and then filling the cylinders with inert gas / CO₂

See in detail

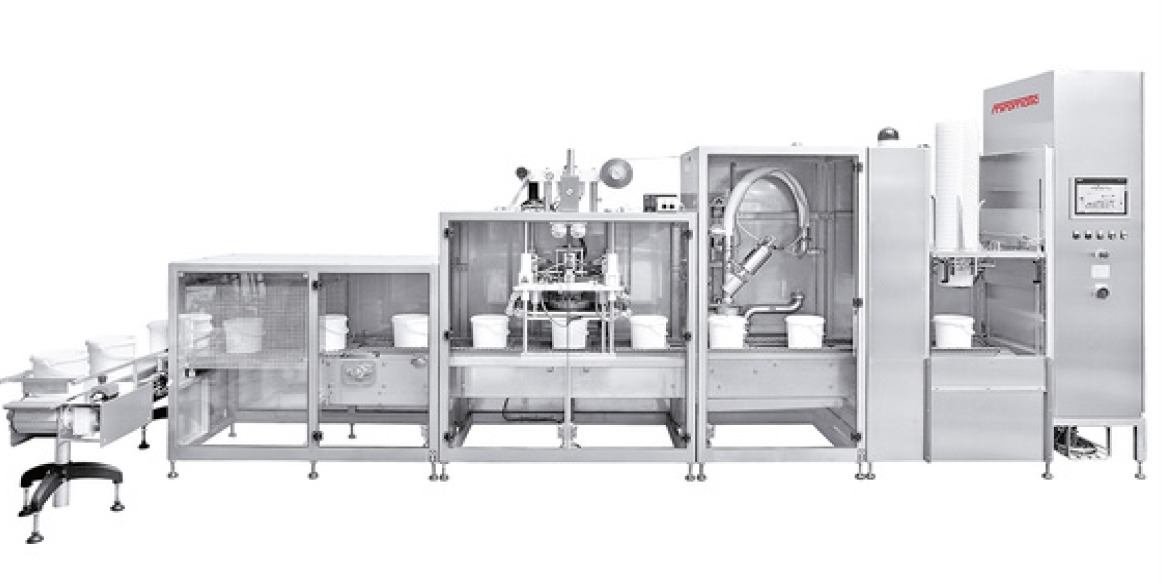

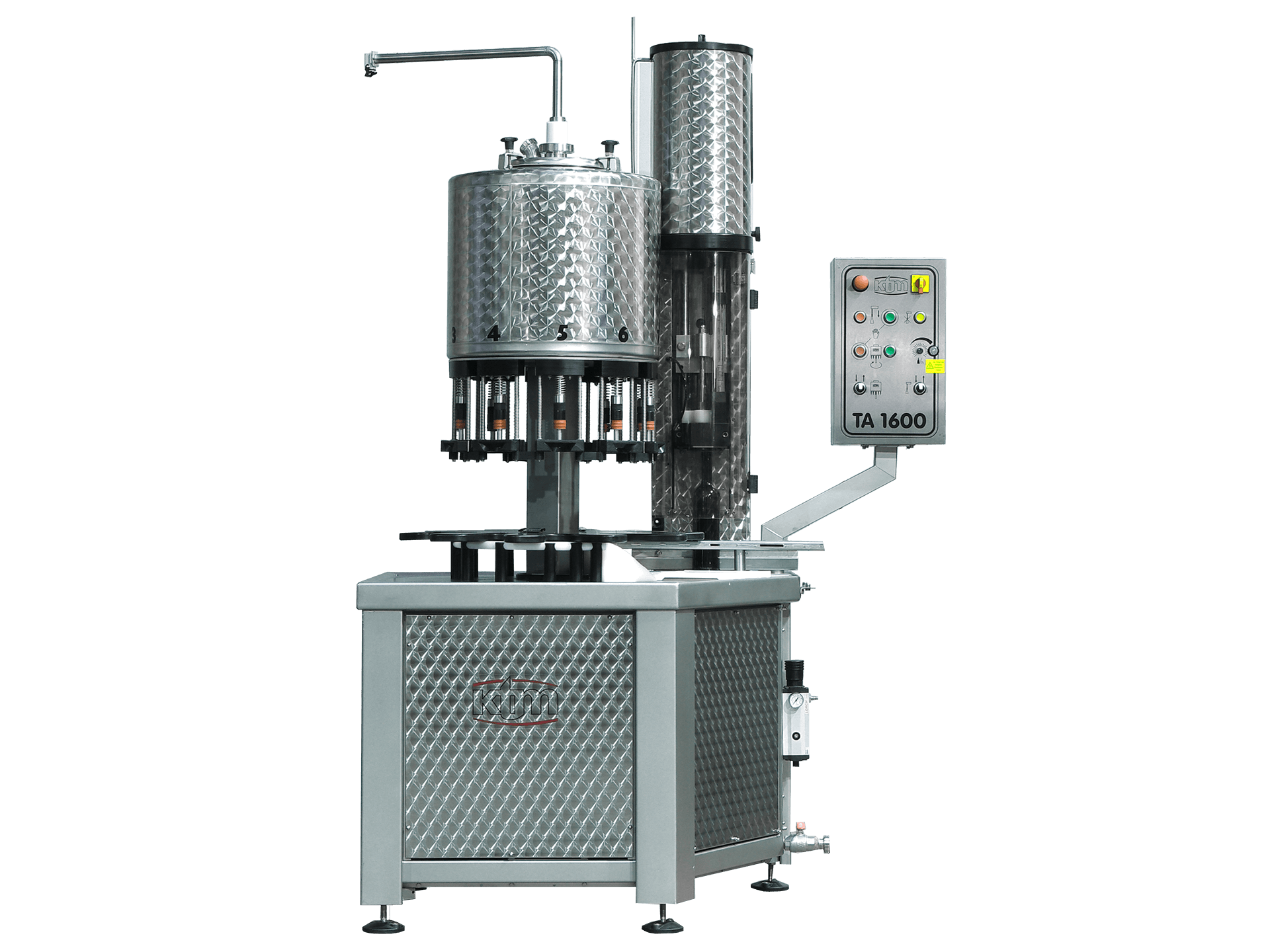

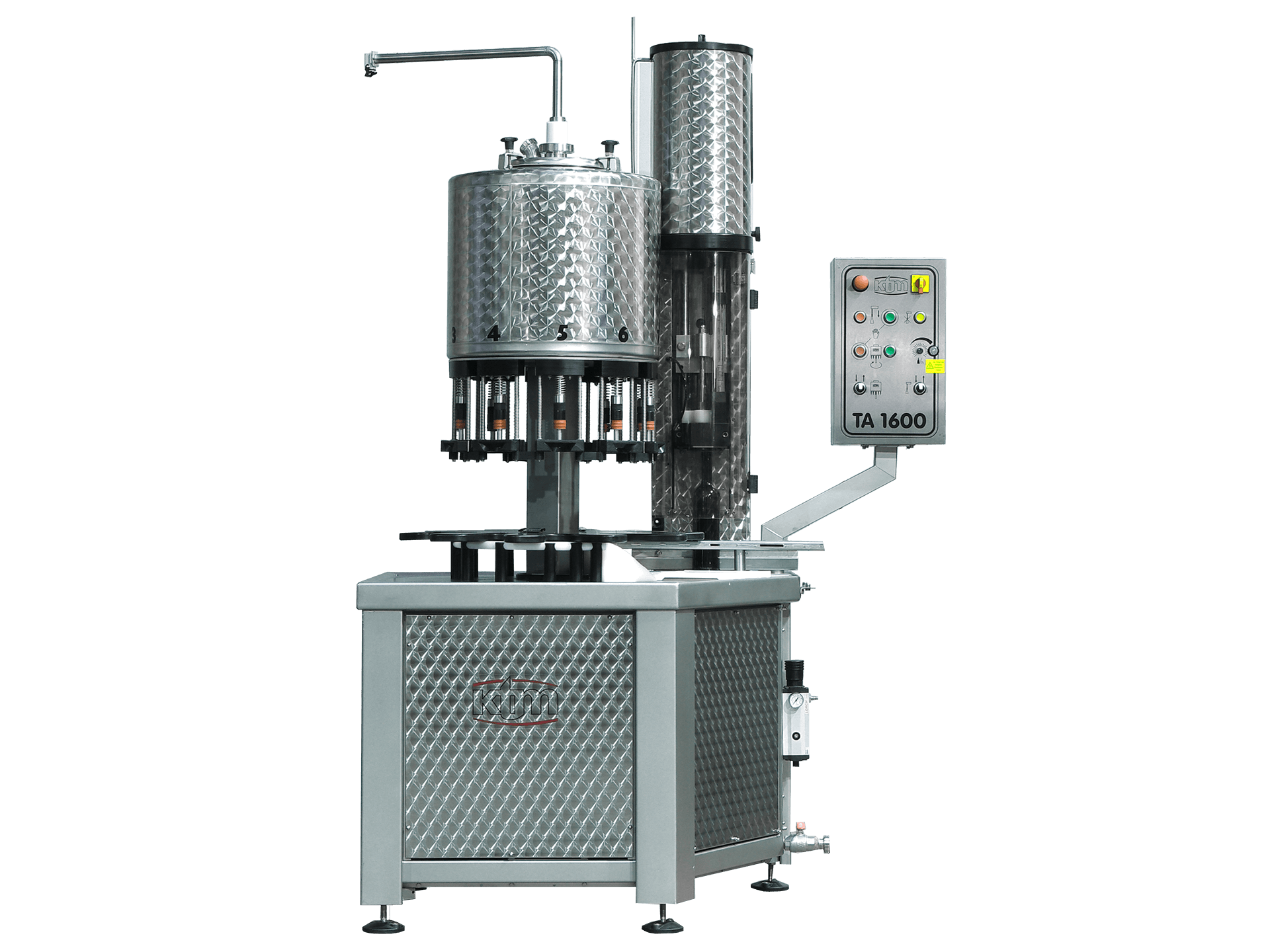

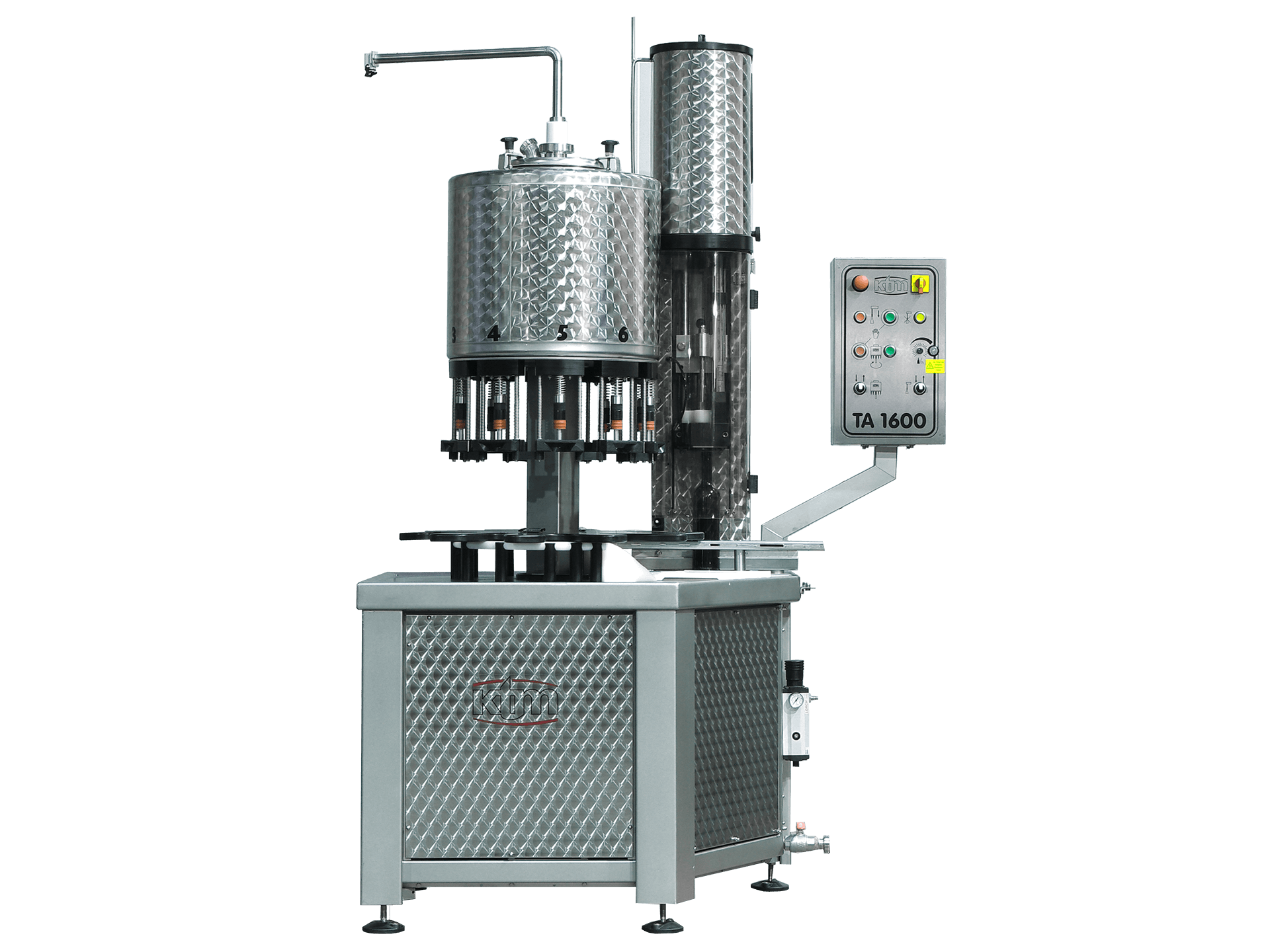

Bottle filling and capping machine TA1600

Drop pressure filler and capper in one unit for MCA or crown caps

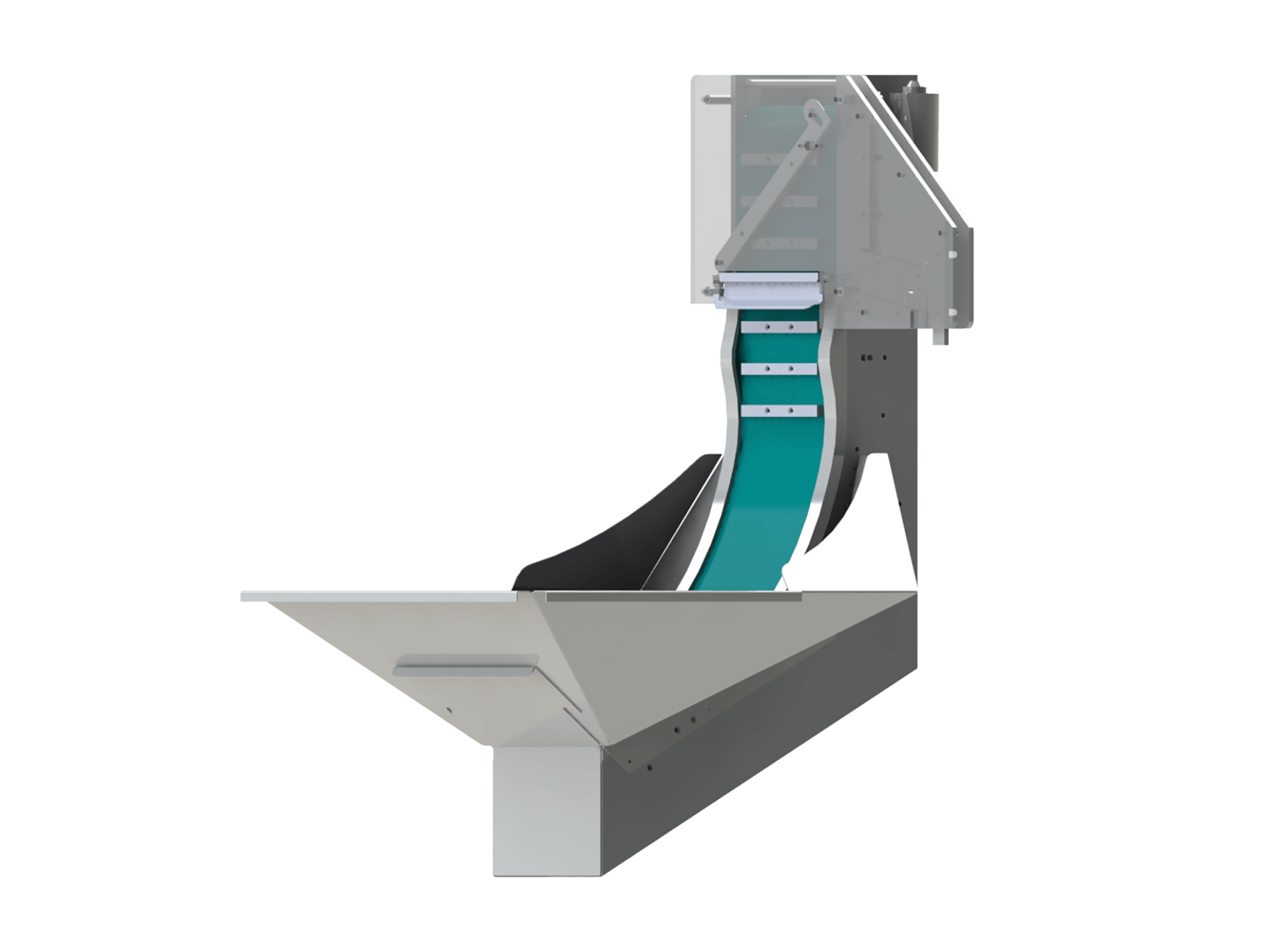

See in detailFilling technology

Our filling technology ensures precision and efficiency throughout the entire filling process, regardless of the various viscosities of the liquids. Find out how we can support you.

All products

Bottle filling and capping machine TVA

The perfect combination - KTM fillers and cappers for all closure types

See in detail

Vacuum inert gas station TVI

For evacuating and then filling the cylinders with inert gas / CO₂

See in detail

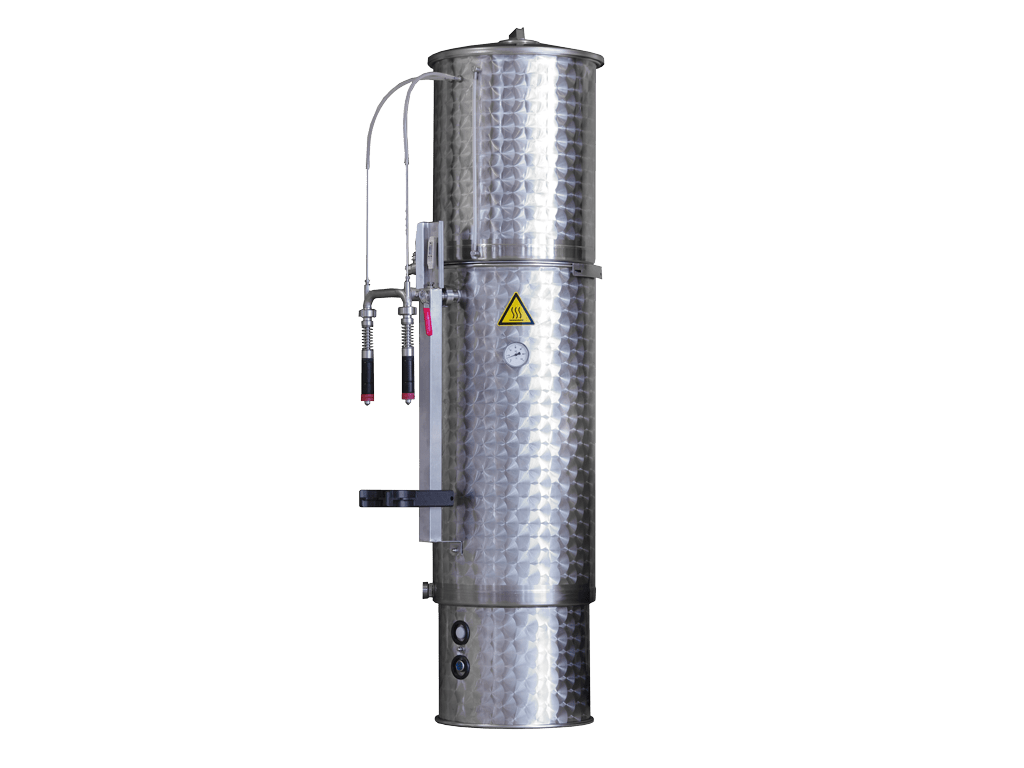

Hot bottle filler / Pasteur THA100-9 / THA100-18

Gently heat fruit juices and fill them into bottles or bag-in-boxes!

See in detail

Bottle filling and capping machine TA1600

Drop pressure filler and capper in one unit for MCA or crown caps

See in detail

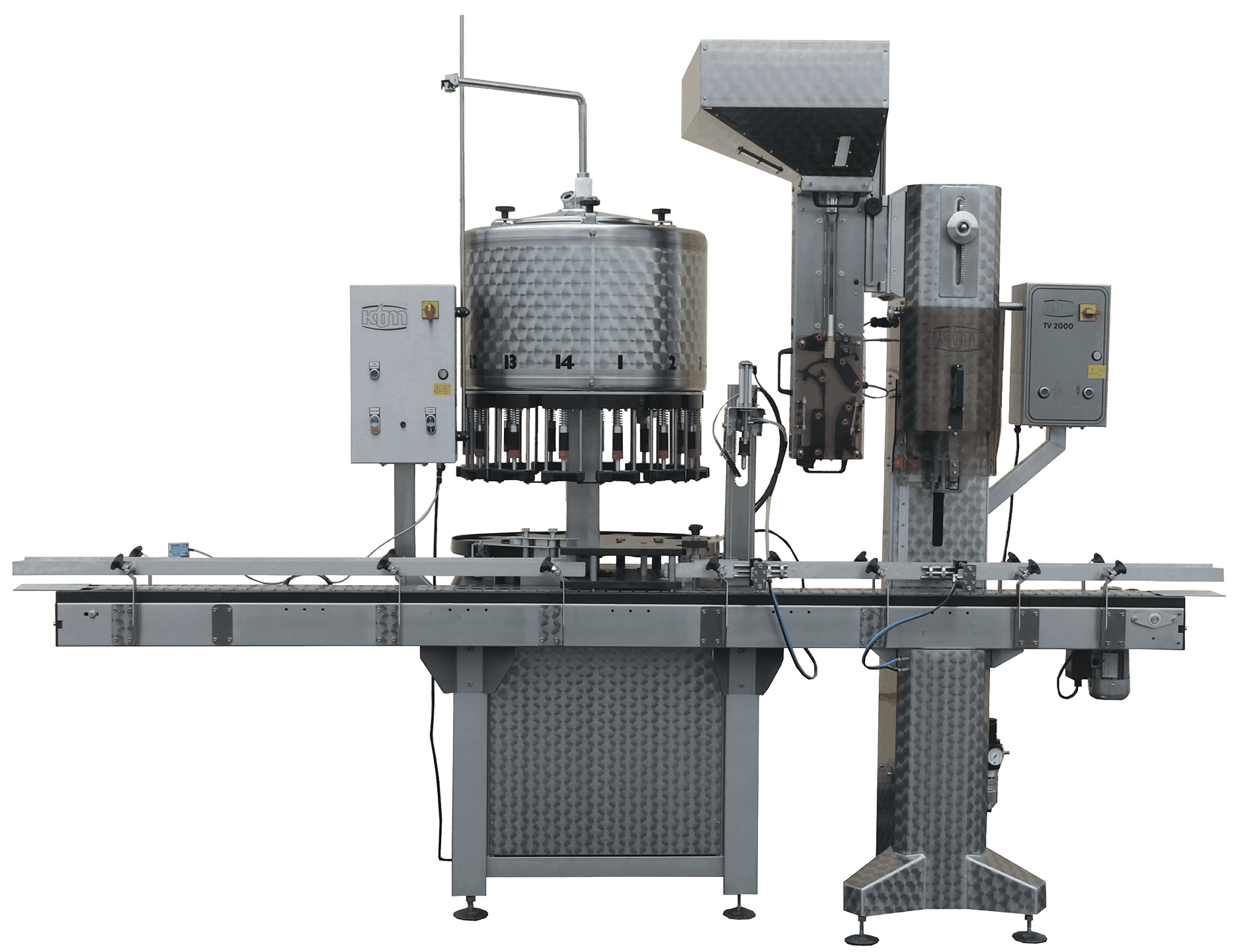

Round filler TA10 / TA14 / TA16

Drop pressure rotary filler with 10/14/16 filling stations

See in detail

Sealing technology

Our capping technology ensures reliable and precise capping of containers - efficiency and safety in the packaging process.

All products

Bottle filling and capping machine TVA

The perfect combination - KTM fillers and cappers for all closure types

See in detail

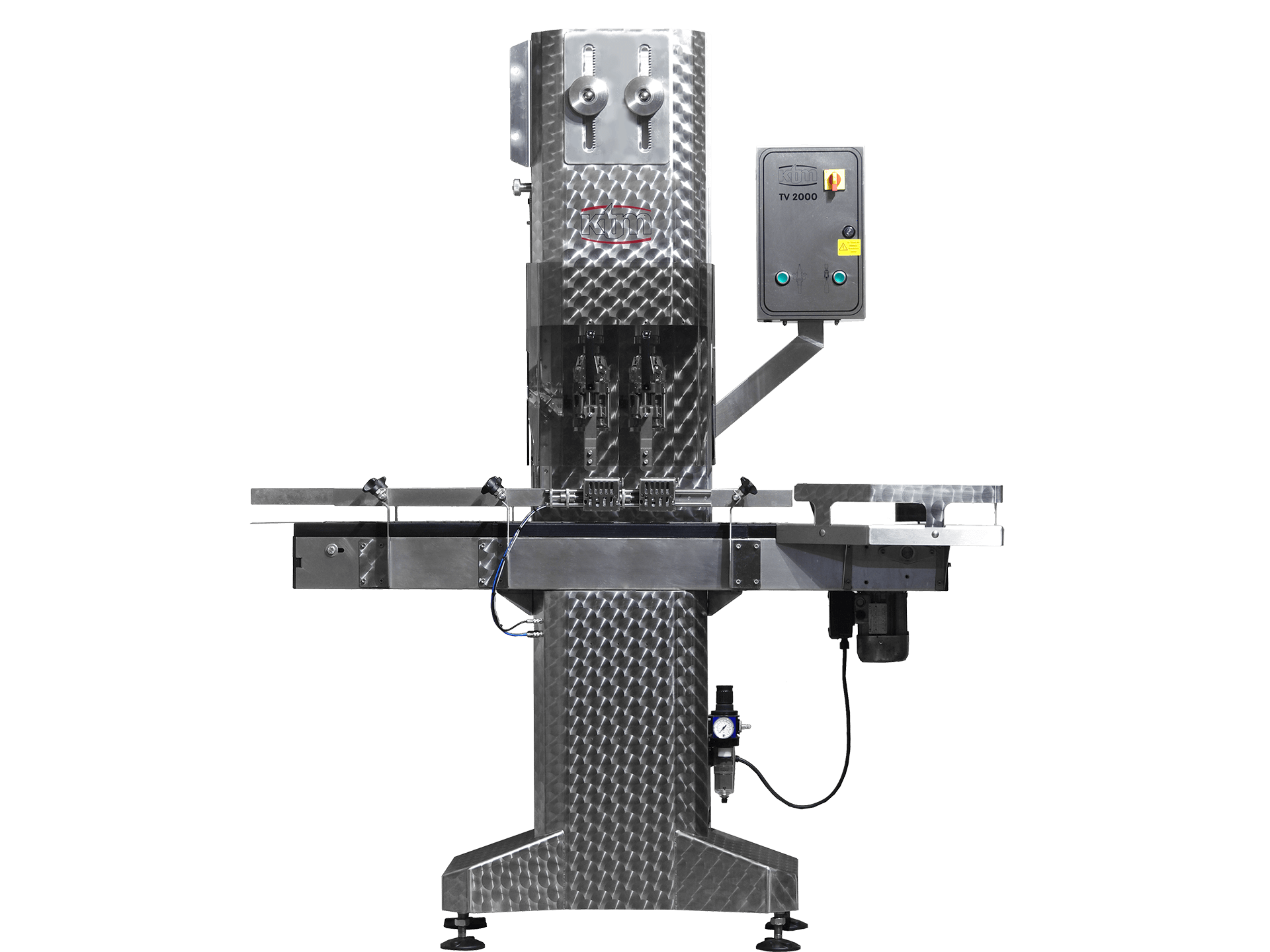

Fully automatic capper TV2000

Fully automatic capper for capping bottles and other containers (wines, other liquids) in small and large batches.

See in detail

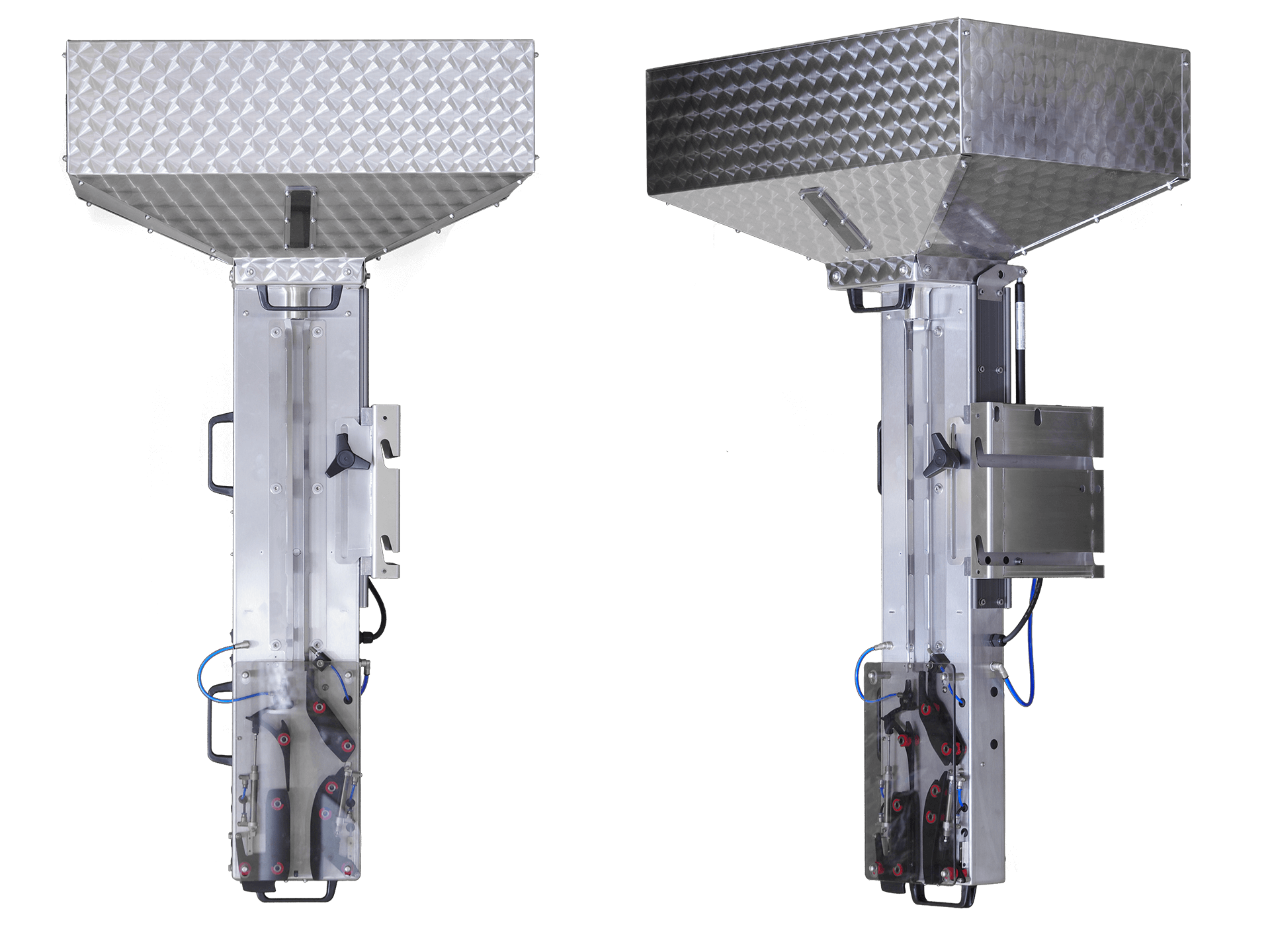

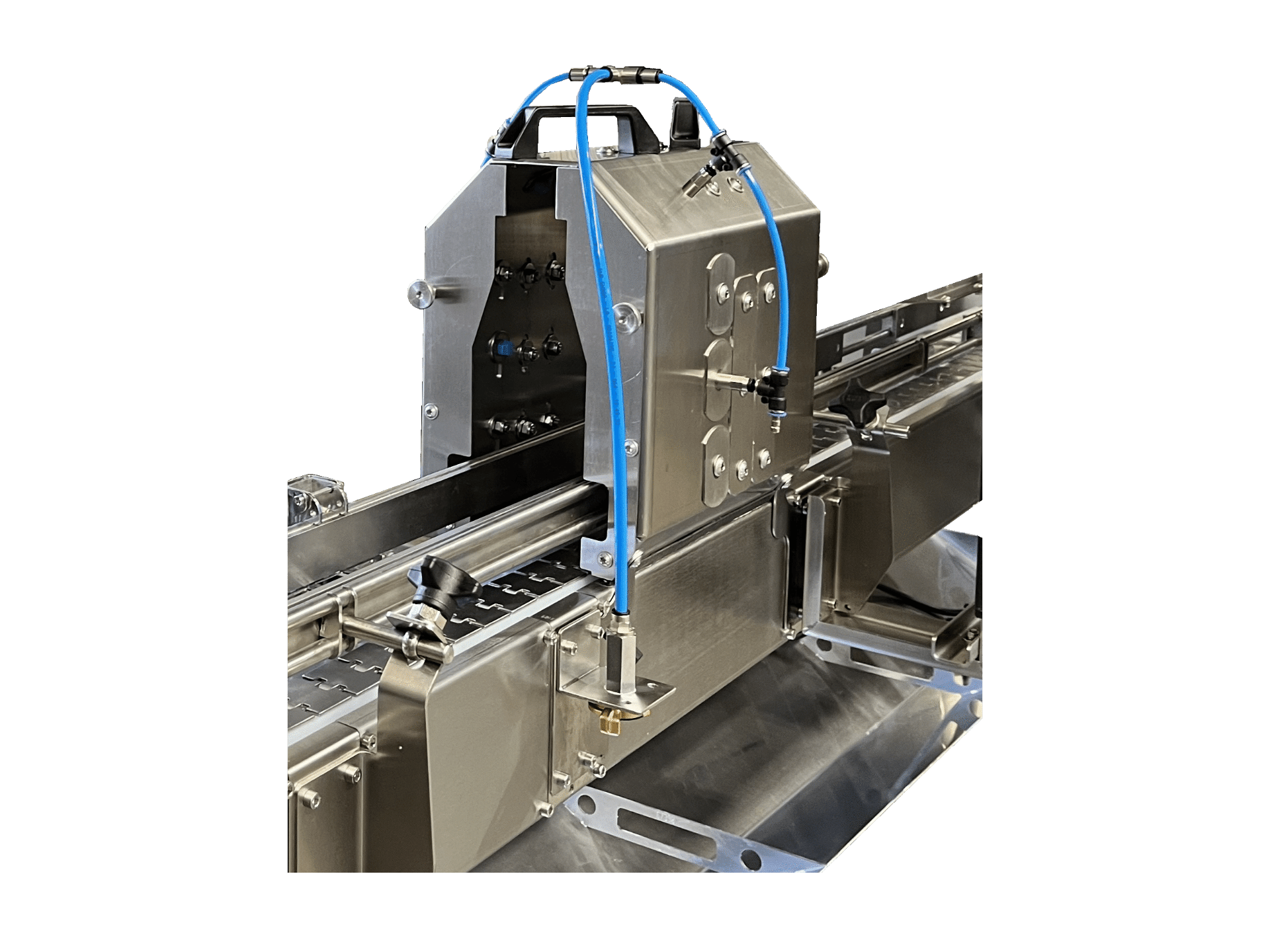

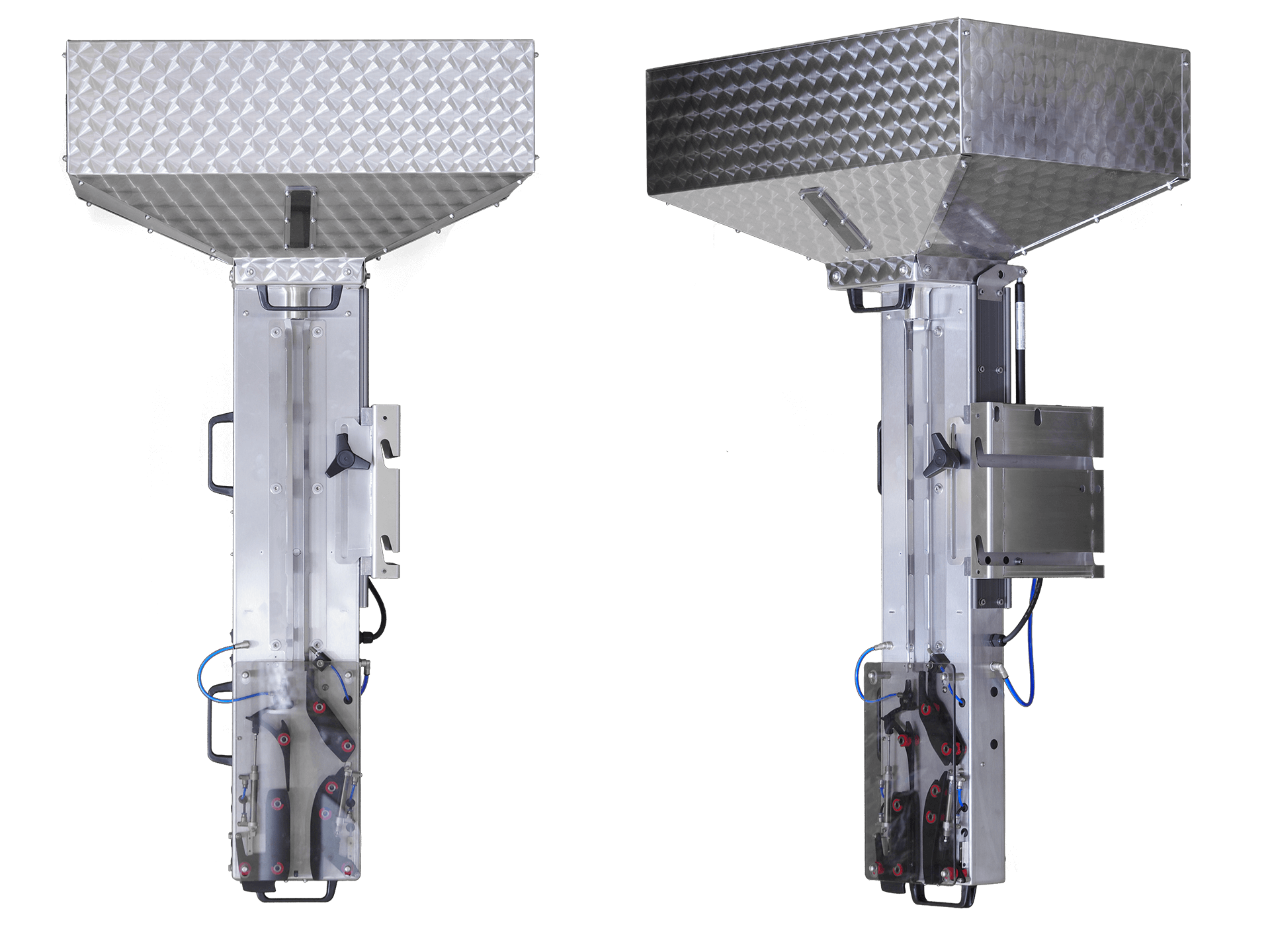

Sorter TSL (LongCap)

Sorting and placing unit for LongCaps Accurate feeding, capping and stocking of the caps in one device

See in detail

Semi-automatic capper TV900

Semi-automatic capper for sealing screw or twist-off cap bottles. Easy adjustment to bottle diameter and height

See in detail

Fully automatic capper TV2000 Twin

Combination machine with 2 ready-to-use capping stations - No changeover time when changing from one type of closure to another

See in detail

Bottle filling and capping machine TA1600

Drop pressure filler and capper in one unit for MCA or crown caps

See in detail

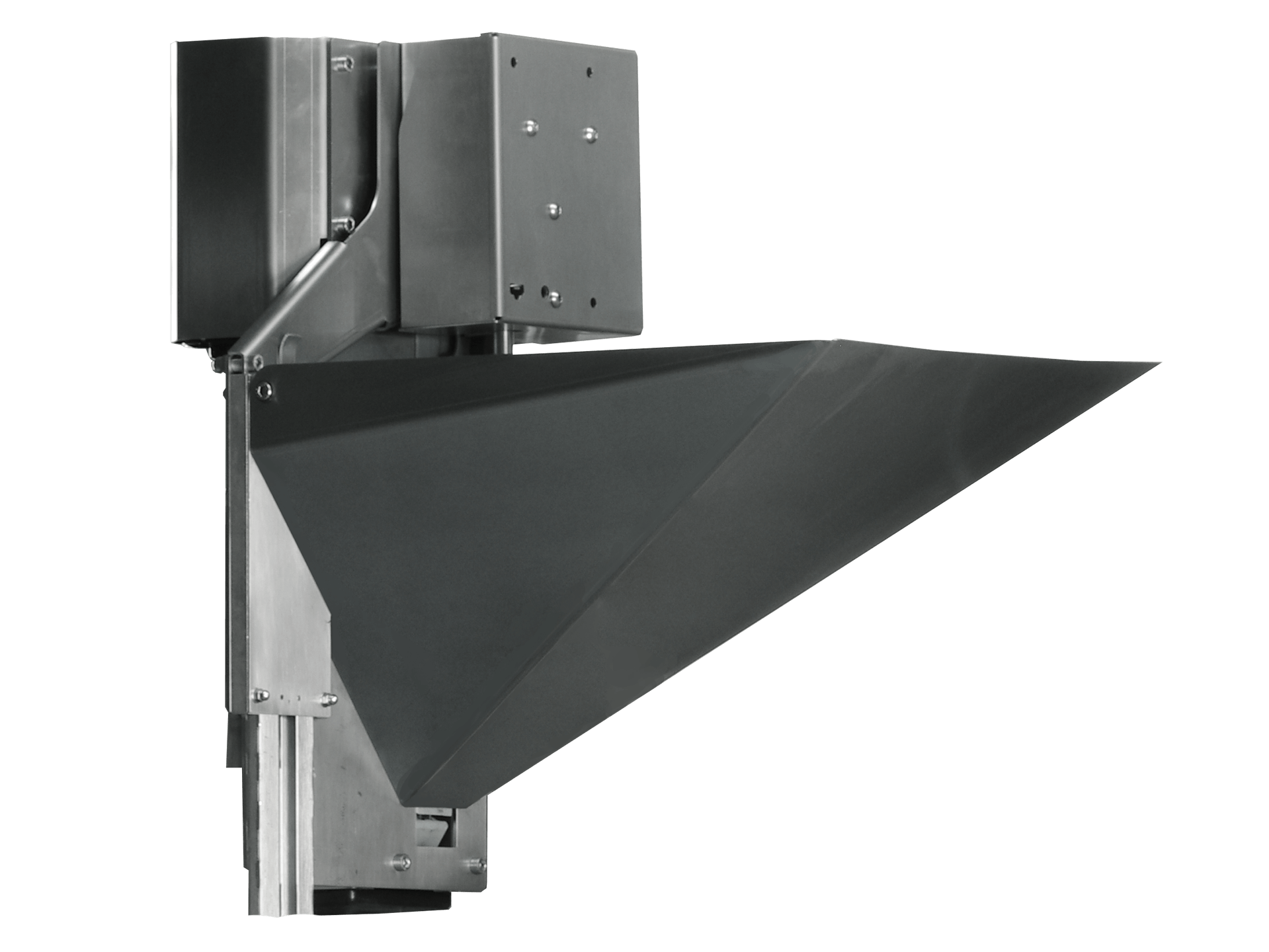

Sorting technology

Our sorting technology automates the sorting process using advanced sensors and mechanisms. Our products significantly increase productivity and quality.

All products

Sorter TSL (LongCap)

Sorting and placing unit for LongCaps Accurate feeding, capping and stocking of the caps in one device

See in detail

Hot filler

Hot filling technology enables the precise filling of containers with hot liquids. Our advanced solutions guarantee efficiency and safety in the hot filling process.

All products

Hot bottle filler / Pasteur THA100-9 / THA100-18

Gently heat fruit juices and fill them into bottles or bag-in-boxes!

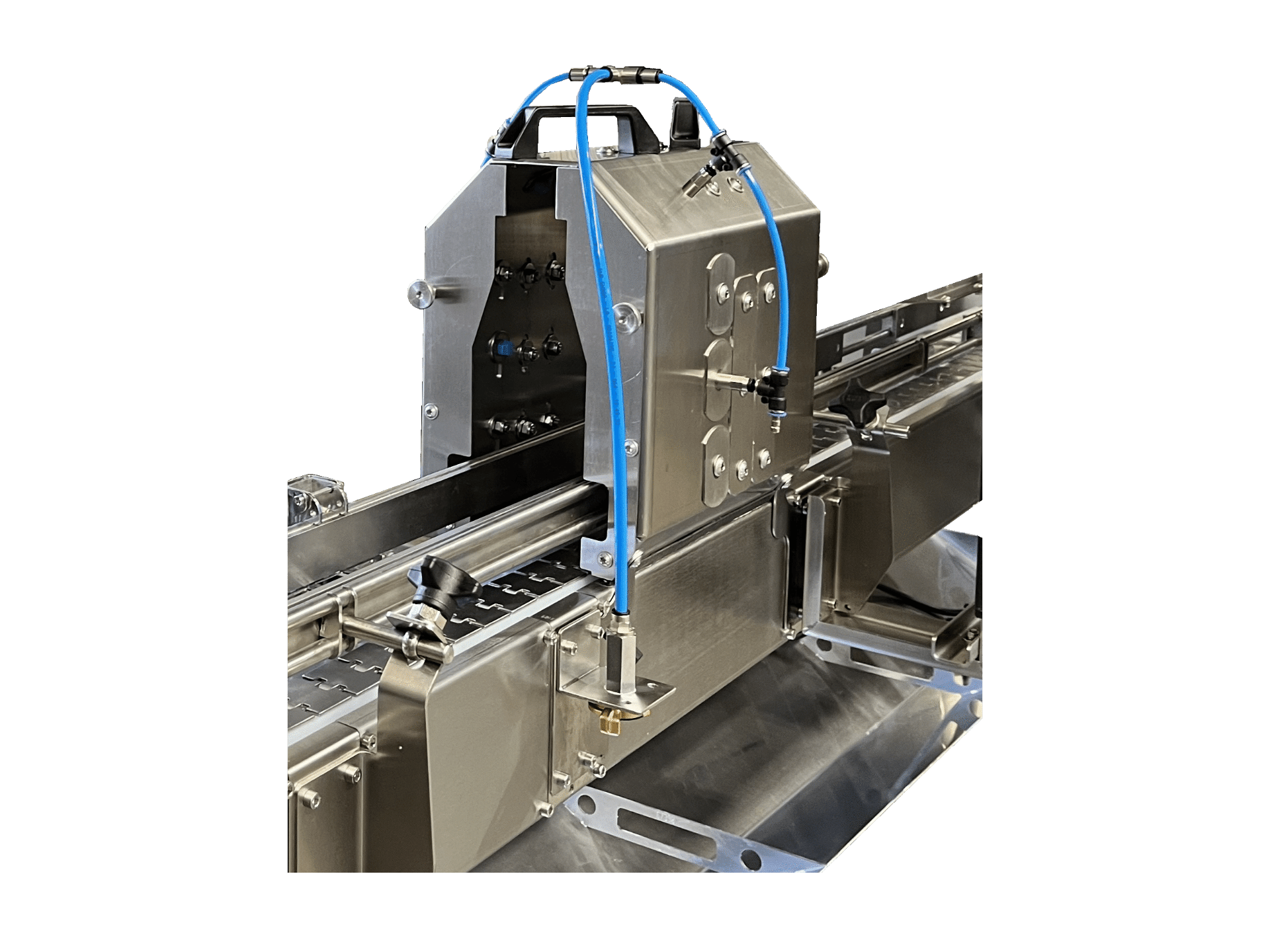

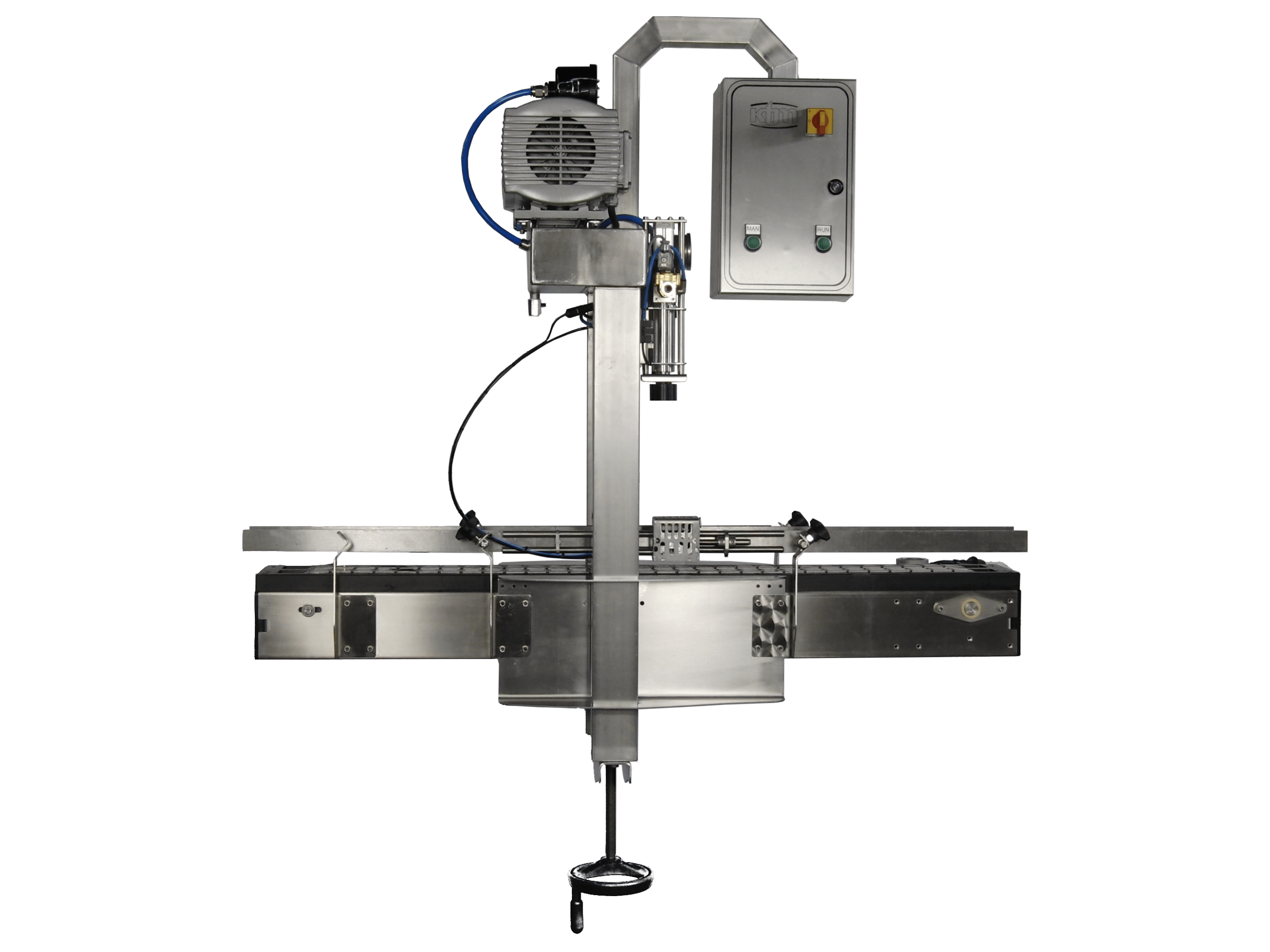

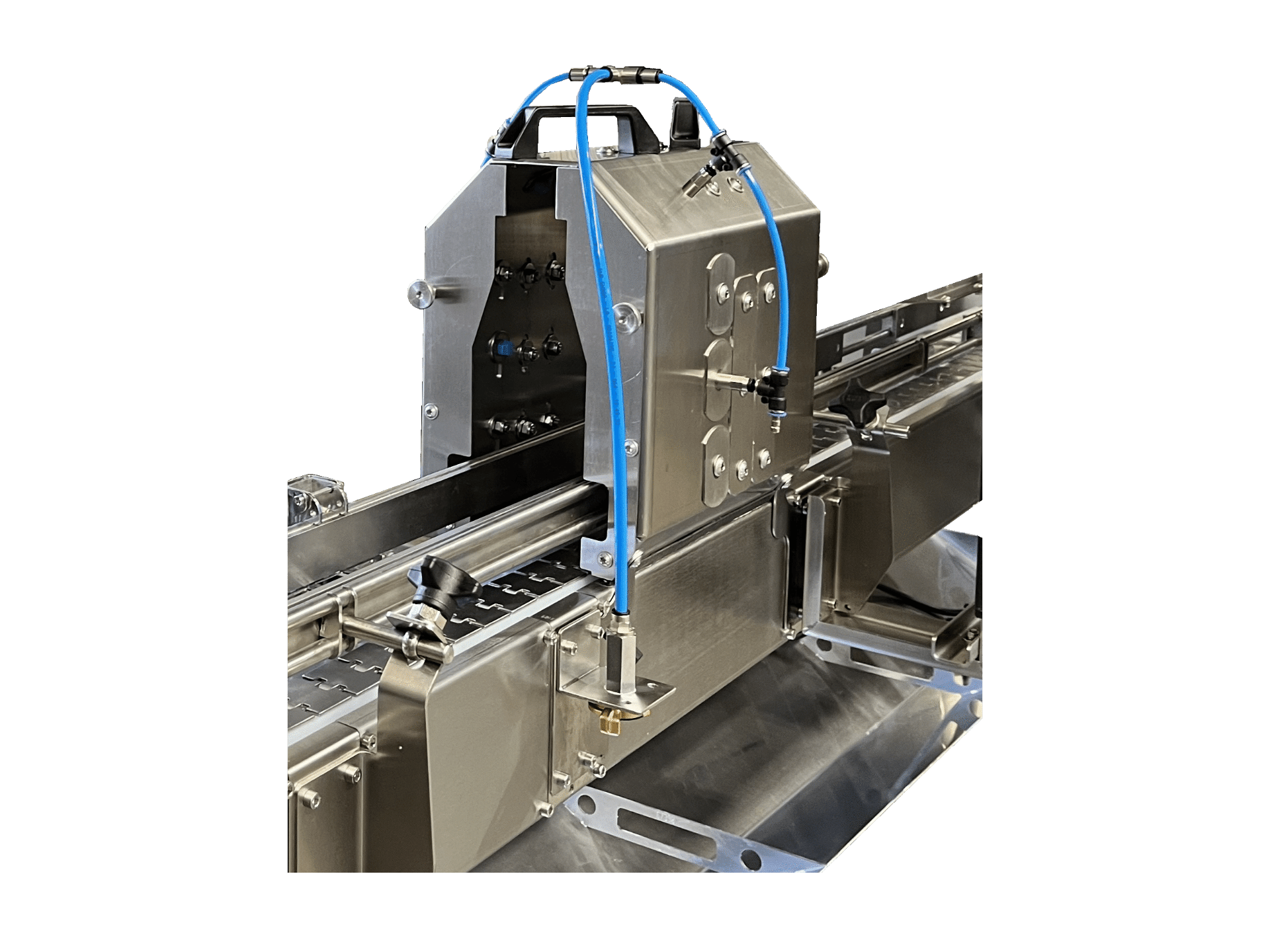

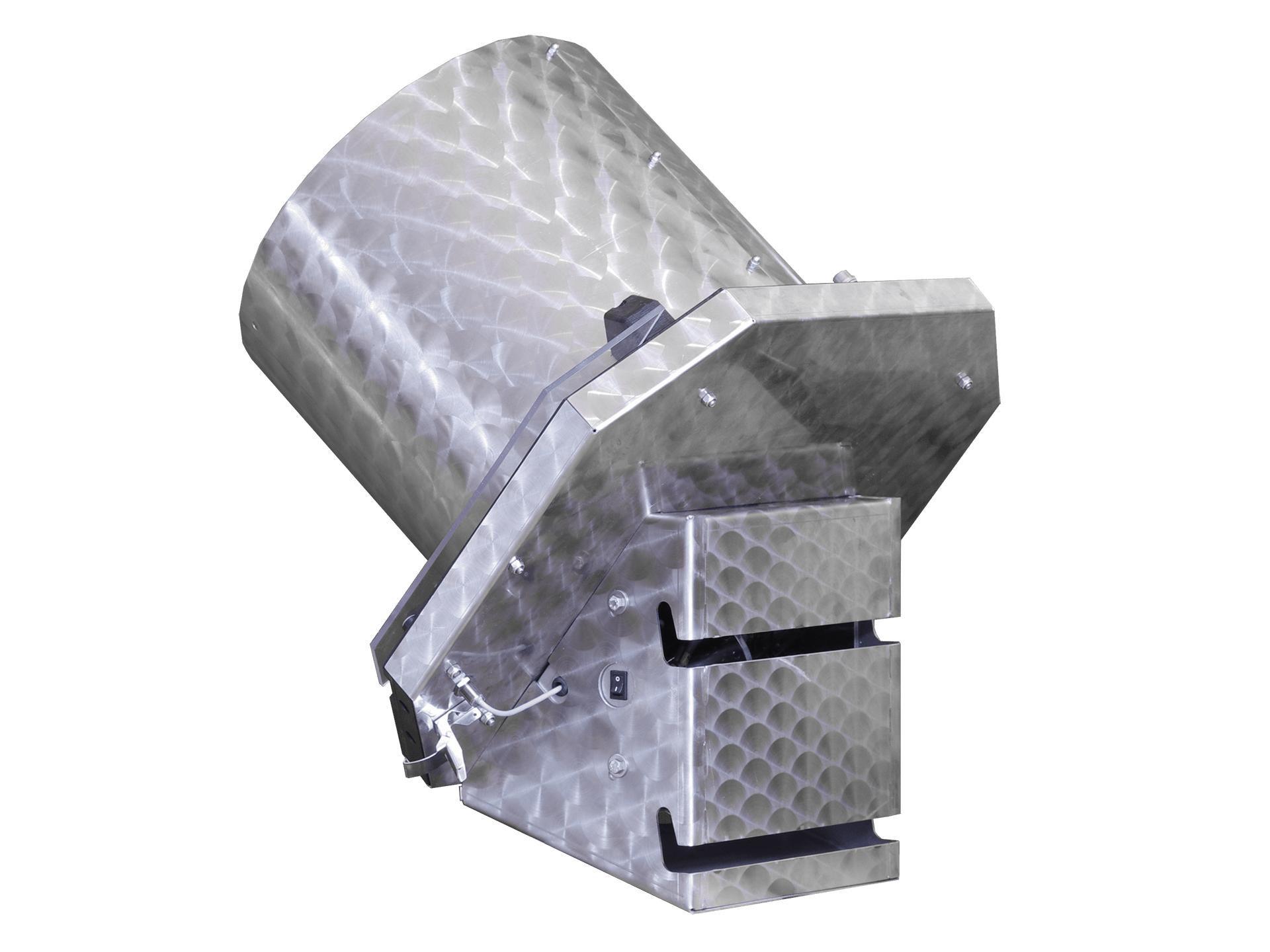

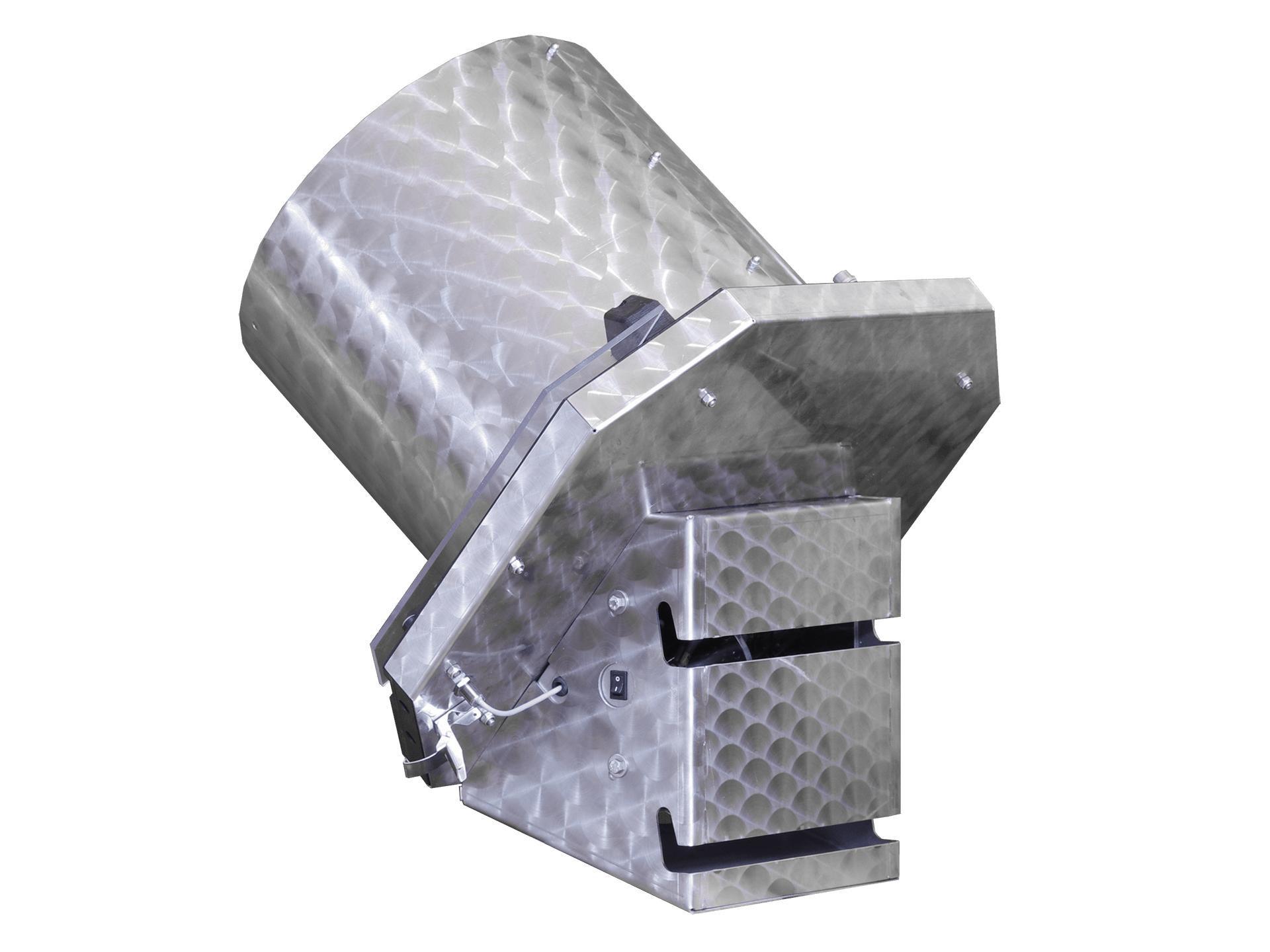

See in detailSchwefler

Our Schwefler offers flexible spraying options and is made of durable materials. Sterilization takes place by placing the bottle neck on the spray nozzle.

All products

Red wine technique

Our red wine technology includes closed tanks and open tanks for various requirements. The immersion paddle system (TFL) and barrique storage round off the range.

All products

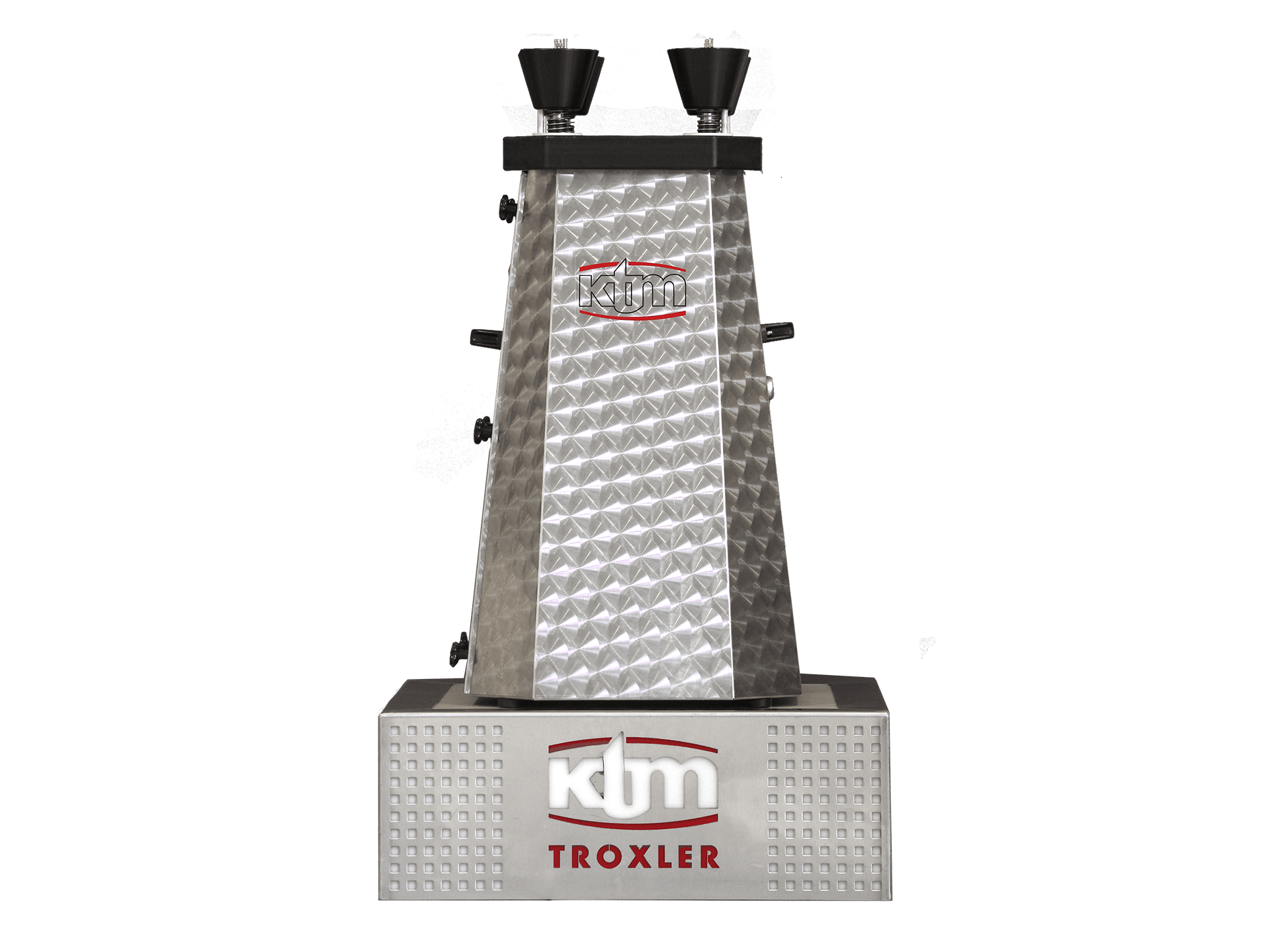

We are KTM Troxler

As a third-generation family business, KTM-Troxler offers solutions for filling and capping liquids. Our outstanding quality standards and in-house developed products ensure a high level of customer satisfaction - Made in Germany. Always open to new ideas - get to know us better!

Always open to new ideas - get to know us better!

- third generation

- Made in Germany

- own production

- own developments

- Advice

- Flexible adjustments

- Flexibility

- Experience

- Competence

Get in touch with us

Every project and every requirement for our products is as individual as the needs of our customers. Let us advise you and we will show you solutions that exactly match your needs. We look forward to receiving your enquiry.