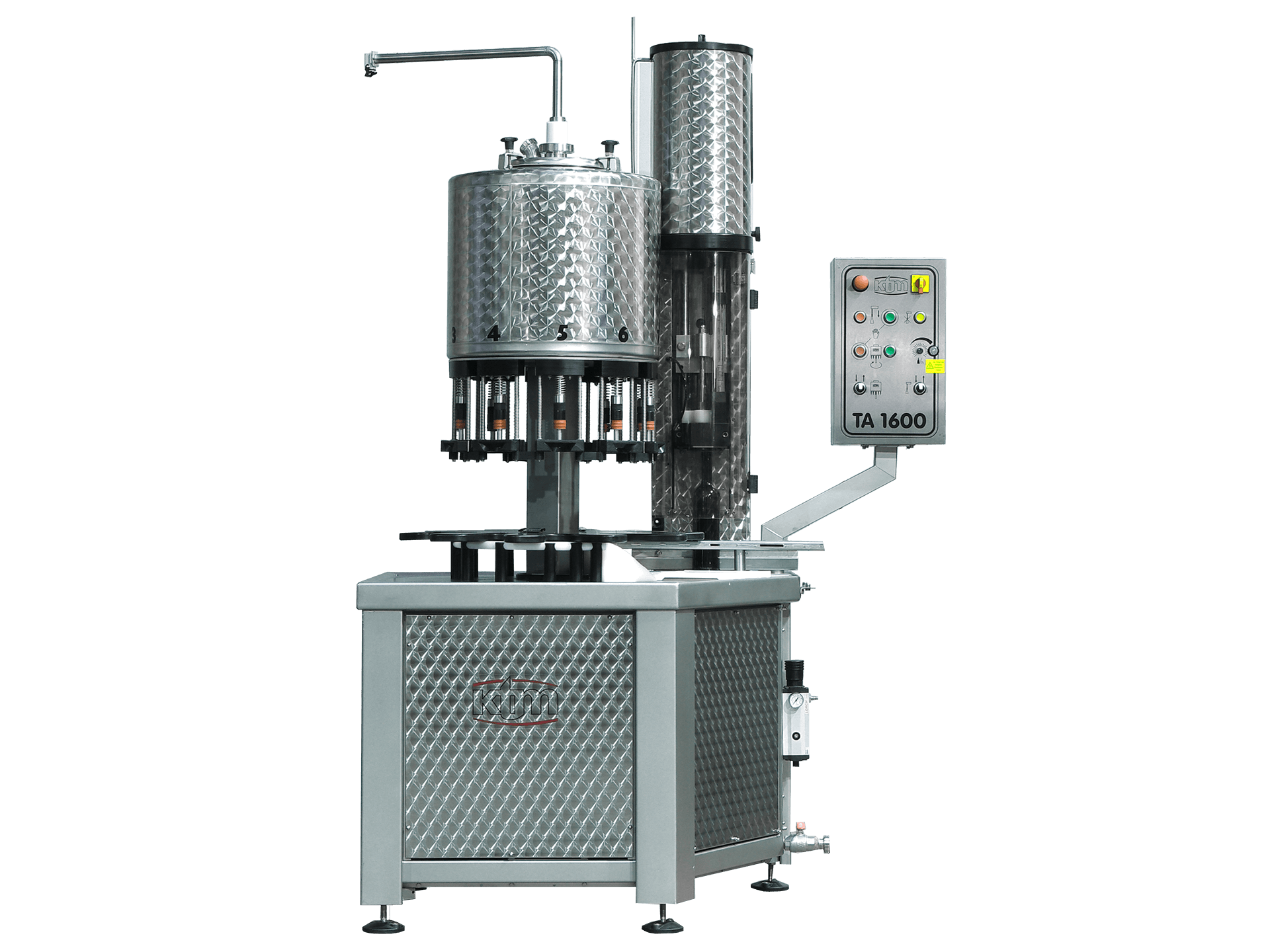

Bottle filling and capping machine TA1600

Drop pressure filler and capper in one unit for MCA or crown caps

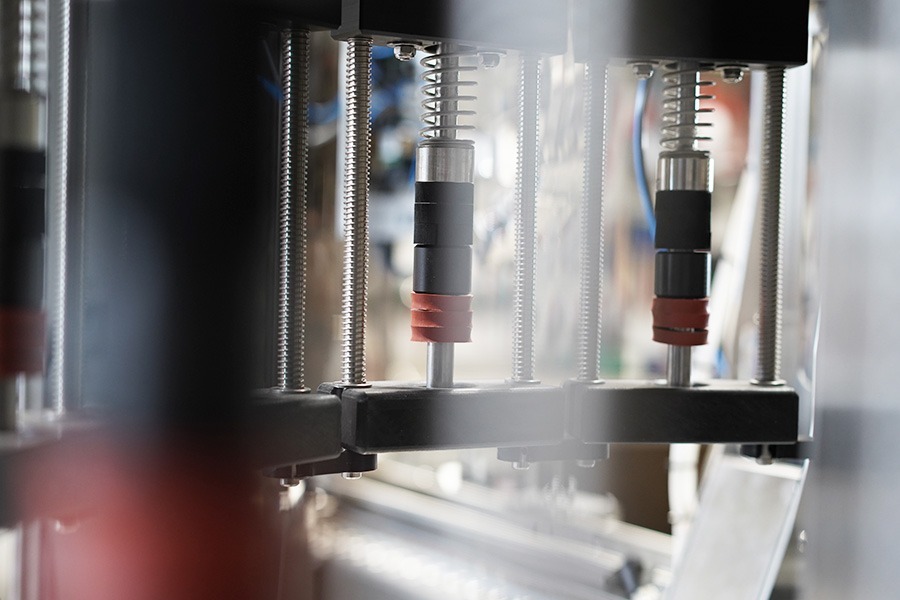

round filler with choice of 10 or 14 filling stations

integrated capper for crown caps or short screw caps Bottles are inserted manually

integrated automatic safety switch-off function

bottle rotary star is quick and easy to replace for different bottle diameters

filling capacity electronically adjustable

fill height infinitely variable

integrated 2-point pump control

filler electrically adjustable to bottle height

also available as a bottle filler for hot juices

How it all began.

Our customers have been using this filling system successfully for over 35 years.

It is still built by us, which speaks volumes about our sophisticated and durable technology.

You can still obtain all spare parts from us even after so many years!

The machine is designed so that the filler and capper fit into the smallest possible space.

Standard versions

TA1600-10

TA1600-14

Technical data

Electrical connection

230V AC / 400 W

Dimensions (L x W x H) [mm]

1100 x 900 x 2200

Weight [kg]

260 / 270

Filling valves

10 / 14

Container volume

90 / 180

Capacity up to [bottles/h]

1600 / 2000

Bottle height [mm] max.

180-340

Bottle diameter [mm]

56-90

Effective air requirement [l/min]

200

Inlet pressure [bar]

6

Optional extras