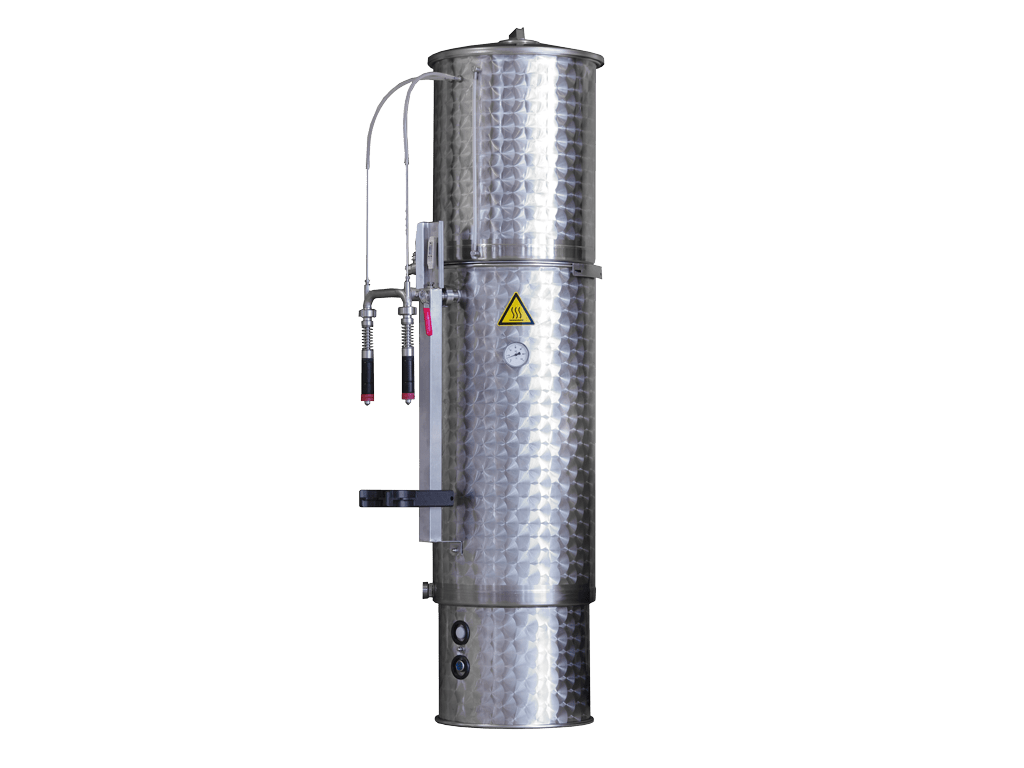

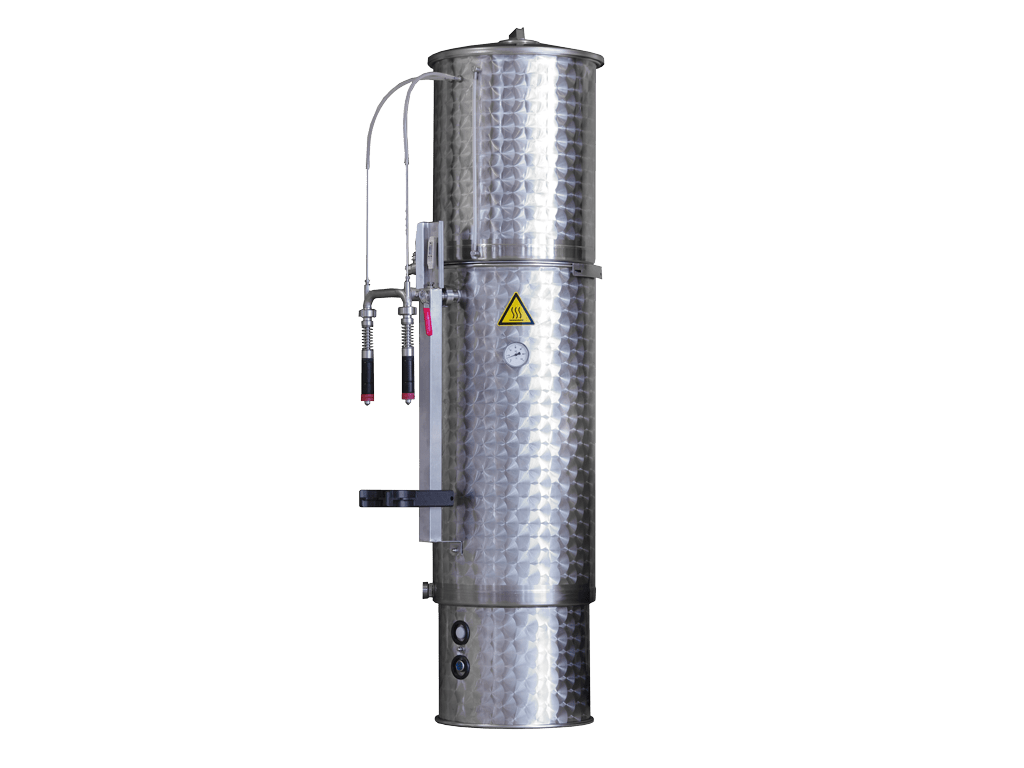

Hot bottle filler / Pasteur THA100-9 / THA100-18

Gently heat fruit juices and fill them into bottles or bag-in-boxes!

available with 1 (heat output 9 kW) or 2 bottle filling valves (heat output 18 kW)

the beginning of the bottling process starts automatically when a bottle is pushed under the valve and stops when it is full

fill height, bottle diameter and bottle height can all be easily adjusted

switch over to optionally available bag-in-box filling device in just a few steps

water bath electronic temperature control

controllable juice outlet temperature and display with digital thermometer

dry run protection provided by a float switch in the water bath

Bag in Box:

The bag-in-box filling device allows you to retrofit the hot bottle filler for filling bags in just a few steps.

During filling, the mouth of the bag-in-box is fixed in place with a retaining claw.

A sealing device facilitates the press fit of the closure.

Standard versions

THA100-9

9 kW with one filling valve

THA100-18

18 kW with two filling valves

THA100-BIB

with bag-in-box device

Technical data

Electrical connection

400V AC (9kW - 16A | 18kW - 32A)

Dimensions (L x W x H) [mm]

440 x 440 x 1580

Weight [kg]

41 / 43

Filling valves

1 / 2 / Bag-in-box

Juice storage container [l]

65

Water reservoir [l]

100

Capacity up to [bottles/h]

130 / 200

Optional extras