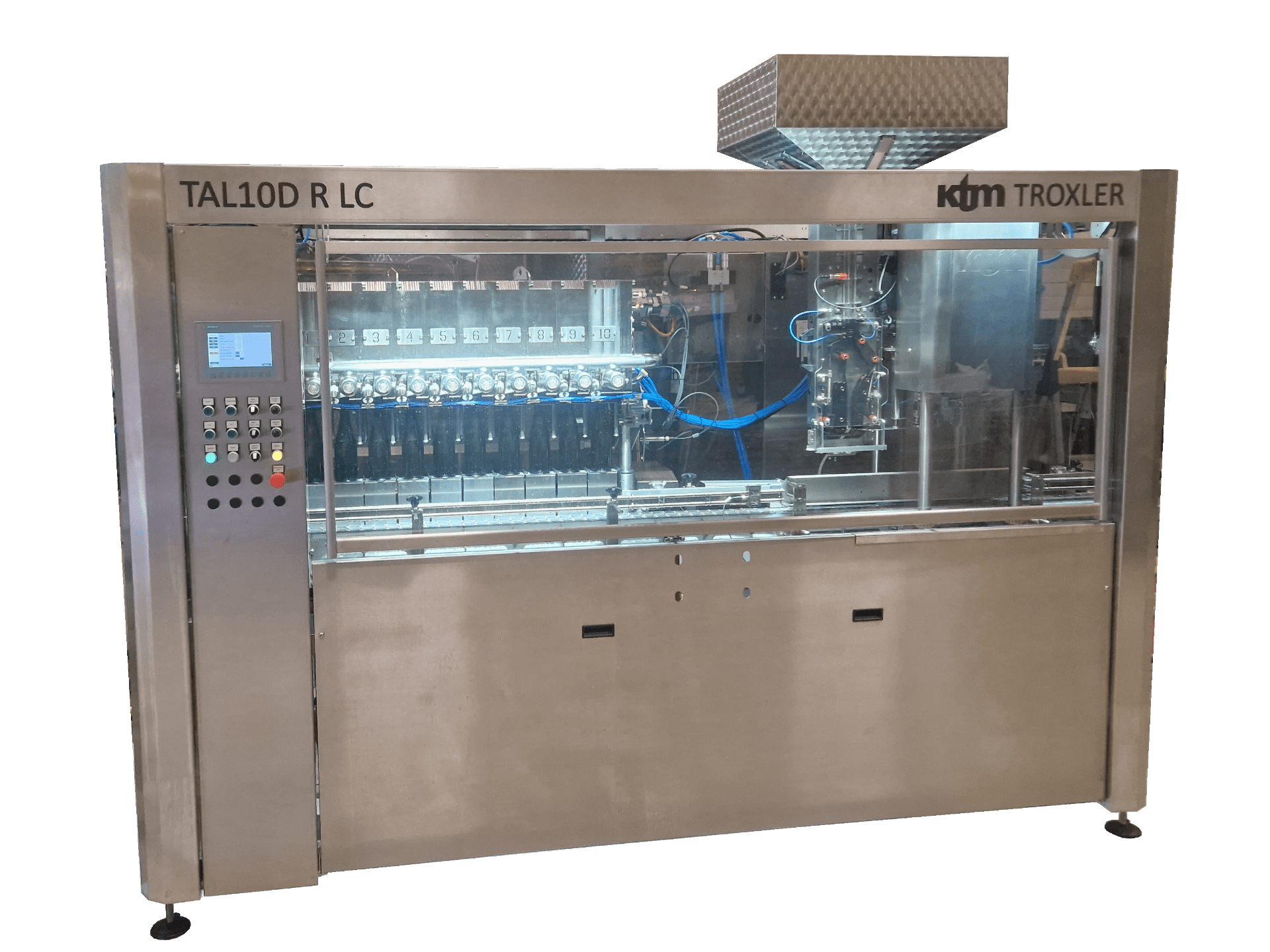

Linear filler TAL

Linear filler

6 - 20 counter-pressure filling valves for carbonated beverages such as (beer, sparkling wine, lemonade, etc.)

Also available as a drop pressure or piston filler

No waiting times during bottle infeed and outfeed thanks to innovative bottle guidance concept. The next bottles are already being replenished during filling

Filling capacity up to 3000 bottles/h

Integrated bottle level compensation

Compact elongated design

Central visualization of all process parameters (pressures, fill level, temperature) on the intuitively designed touchscreen

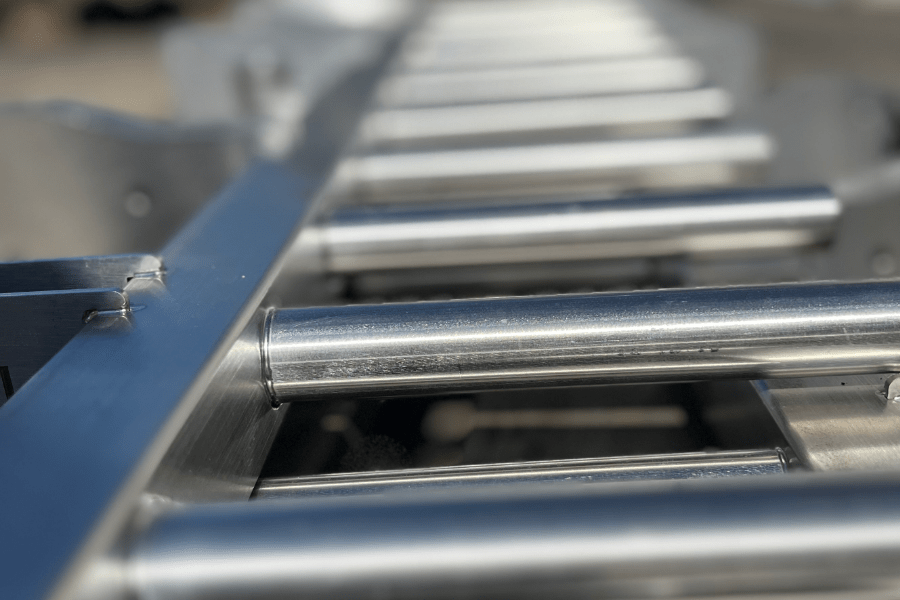

Hygienic design of the complete filling system (diaphragm valves, low-gap screw connections, dead space arm, etc.)

easy to clean: CIP (Cleaning in Place) and SIP (Sterilization in Place) capable

Our rinser and/or capper can be integrated into a monoblock

Our multi-functional talent, usually with counter-pressure filling valves for filling carbonated drinks.

Beverage cans are also possible with the appropriate equipment.

Available on request as a gravity filler for still drinks or as a piston filler for pasteurized products.

Expansion options:

The TALD counter-pressure filler can be combined very well with our TV2000 or TV2000TWIN capper. This makes it possible to close the following closures at one or two capping stations: LongCaps, ShortCaps, natural corks, crown corks, Twist and Plopp, LongCaps with internal thread.

Standard versions

TAL10D

Counter pressure filler with 10 filling valves

TAL12D

Counter-pressure filler with 12 filling valves

TAL14D

Back pressure filler with 14 filling valves

TAL16D

Back pressure filler with 16 filling valves

Other filling valve variants:

The linear filler can also be equipped with other filling valves:

- TAL-G - Drop pressure valves

- TAL-N - Short tube valves unpressurized

- TAL-P - Piston filler

Technical data

Electrical connection

400V AC / 16A / 4kW

Dimensions (L x W x H) [mm]

2000 / 2200 / 2400 / 2600 x 850 x 2000

Weight [kg]

650 / 700 / 750 / 800

Filling valves

6 / 8 / 10 / 12 / 14 / 16 / 20

Output of still products up to [bottles 0.7 l/h]

2400 / 2800 / 3000 / 3000

Capacity for carbonated products up to [bottles 0.7 l/h]

1800 / 2200 / 2600 / 3000

Bottle height [mm] max.

180-380

Bottle diameter [mm]

55-90

Optional extras