Individual requirements need individual solutions

Custom machine for pre-rolling aluminium roll-on closures

Task definition:

A customer was looking for a machine for pre-rolling aluminium screw caps for home use, e.g. for capping small quantities of bottles. A large number of different closures were to be processed and the conversion was to take place as quickly as possible.

Objective:

The machine should be able to roll on the following closures:

- PP28x15

- PP31.5×24 with oil spout

- PP31.5×24 without oil spout

- MCA28x15

- MCA28x13

The performance was to be around 2000 lids per hour. The stock volume of the sorting plant was to contain at least 1 box (8000 pieces). The machine was to stop automatically after a certain number.

Solution:

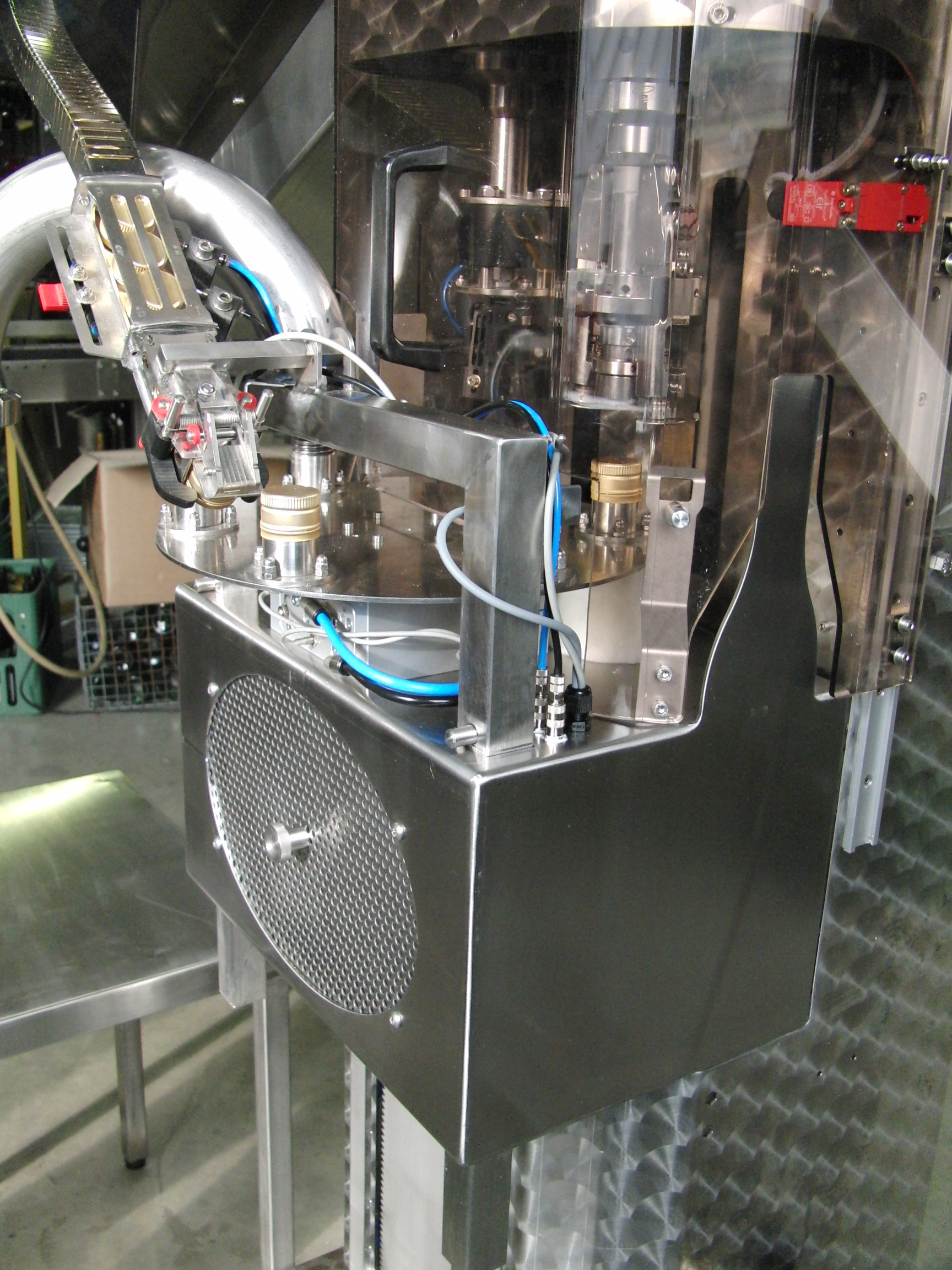

A TV2000 was used as the basic framework for the system. A rotary indexing table with 6 stations continuously cycles the lids. The lids are fed into the lid dispenser in the correct position by a TSB waterfall sorter and a flexible drop channel. This is followed by the 6 cycles of the sealing unit:

- Station: Stripping the lid

- Station: Query whether a lid is present

- Station: Preforming the thread without flanging

- Station: Release the lid using a three-jaw gripper and pneumatic motor

- Station: Blowing out the lid into a cardboard box

- Station: Empty station with query as to whether the lid has been blown out cleanly

The system is also very light (250 kg) and only requires 230 V electricity and compressed air. This solution enables efficient and precise processing of different types of closure while at the same time being easy to operate and quick to change over.

Download

Gallery