When more flexibility is needed again

Mobile filling system

Task definition:

A customer wanted to offer mobile filling services that included both still and carbonated beverages. The requirements included filling with various closures such as short (MCA28x15) and long (BVS30x60) aluminium roll-on closures as well as small (26) and large (29) crown caps. The bottle sizes were to range from 0.2 litres to 1.5 litres and the bottles were to be rinsed out before filling. In addition, Slim, Sleek and Classic aluminium beverage cans were to be filled.

Objective:

The objective was to develop a mobile filling system that could be transported with a Sprinter and a car trailer with a total length of less than 5 metres. The compressor and CO2 bundle were to be transported in the Sprinter, while the filling system including buffer tank, damper, carboniser and filter technology were to be installed on the trailer. Due to the limited payload of the trailer (<= 2.5 tonnes), the machine had to be very light. The desired filling capacity was to be 1500 bottles per hour for counter-pressure filling, 2000 bottles per hour for still products and 1800 cans per hour. The system was to be up and running 30 minutes after arrival.

Solution:

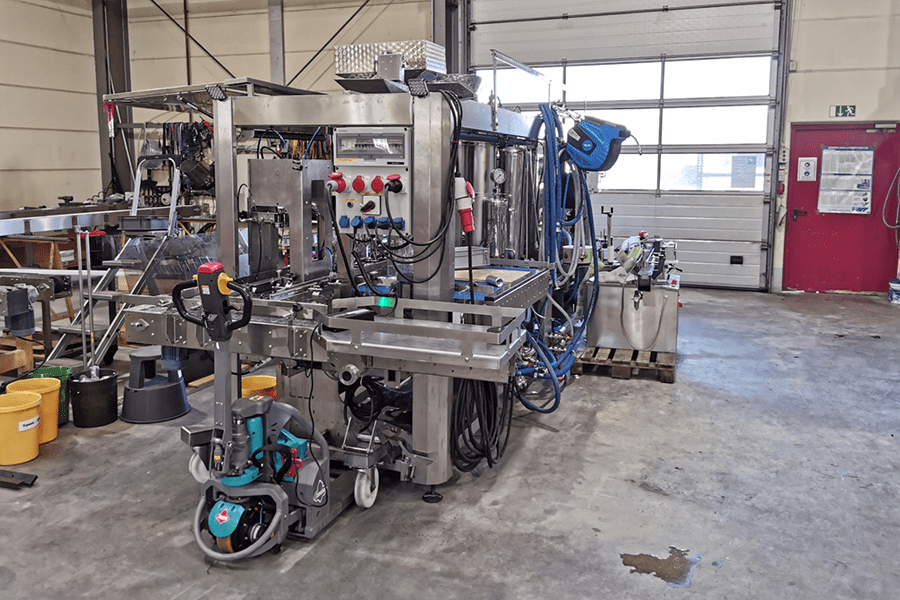

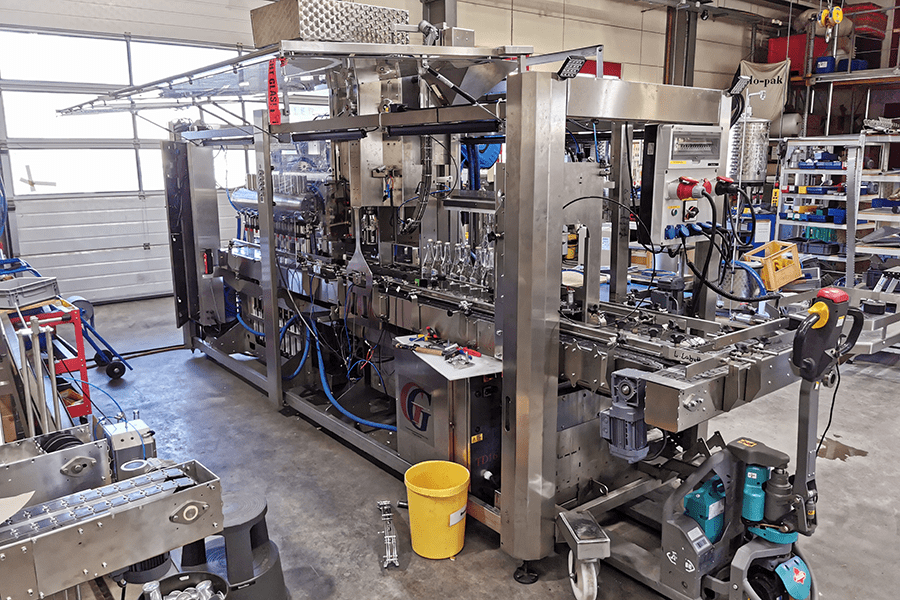

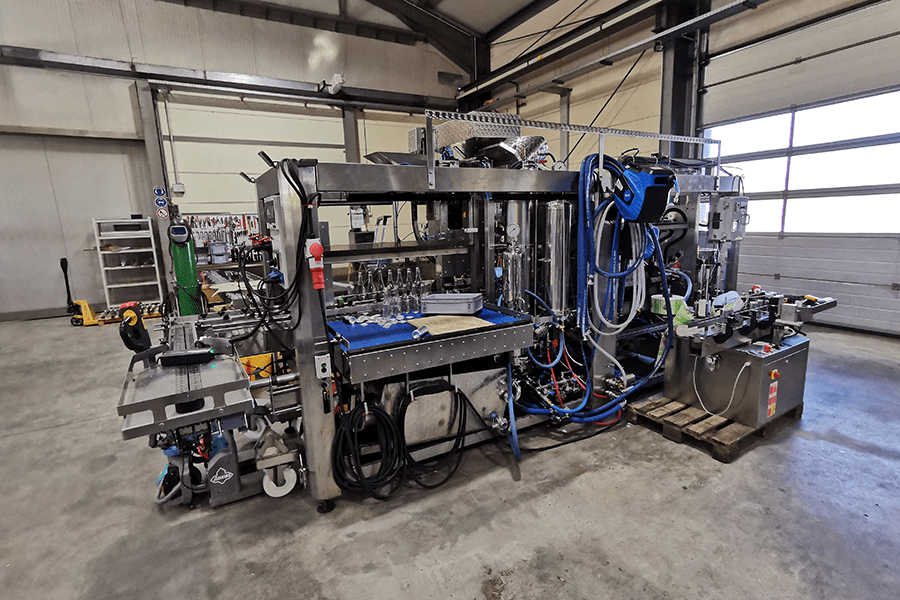

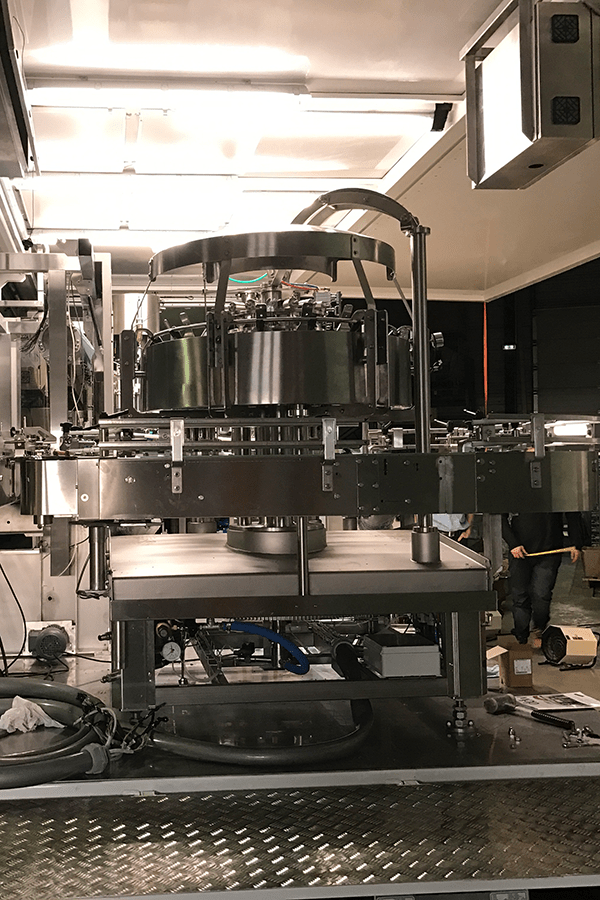

The centrepiece of the system was a 10-position TAL10D counter-pressure filler with rinser and TV2000LC capper. The system was built on rollers and the car trailer could be easily tilted so that the system could be loaded and unloaded using a cable winch. Due to the low weight of the system, it was possible to move it easily in two-person teams or with an electric pallet truck. A large feed table and a fold-down collection table enabled an operator to set up and remove the bottles. All additional components such as the Univog ozone water generator, Gebhardt turbo steam generator, buffer tank, the KTM TCA carboniser, two cartridge filter housings and power and water distributors were installed in and on the system. To operate the system, only the product supply line, CO2, compressed air, electricity and water had to be connected. Thanks to the good carbonation and the electro-pneumatic filling valves, the customer was able to fill the product at temperatures of up to 25°C without refrigeration. The mobile filling system offers a flexible solution for customers who want to fill drinks on site. With its compact design, simple operation and high filling performance, it fulfils the requirements for an efficient and transportable filling solution.

All additional components such as the Univog ozone water generator, Gebhardt turbo damper, buffer tank, the KTM TCA carbonizer, two cartridge filter housings and power and water distributors were installed in and on the system. To operate the system, only the product supply line, CO2compressed air, electricity and water. Thanks to the good carbonation and the electro-pneumatic filling valves, the customer was able to carry out mobile filling without cooling at product temperatures of up to 25°C.

The mobile filling system offers a flexible solution for customers who want to fill drinks on site. Thanks to its compact design, simple operation and high filling capacity, it meets the requirements for an efficient and transportable filling solution.

Download

Gallery