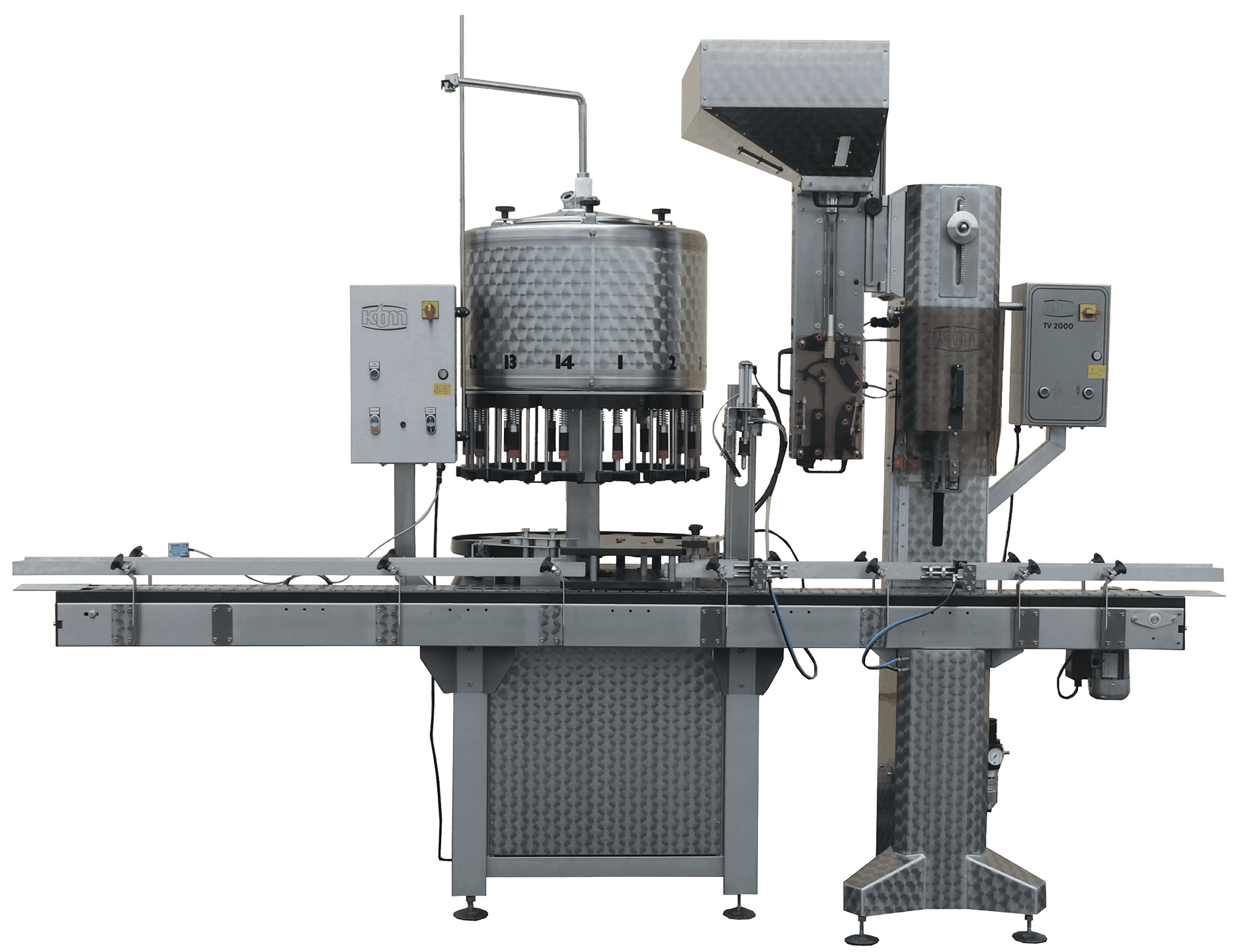

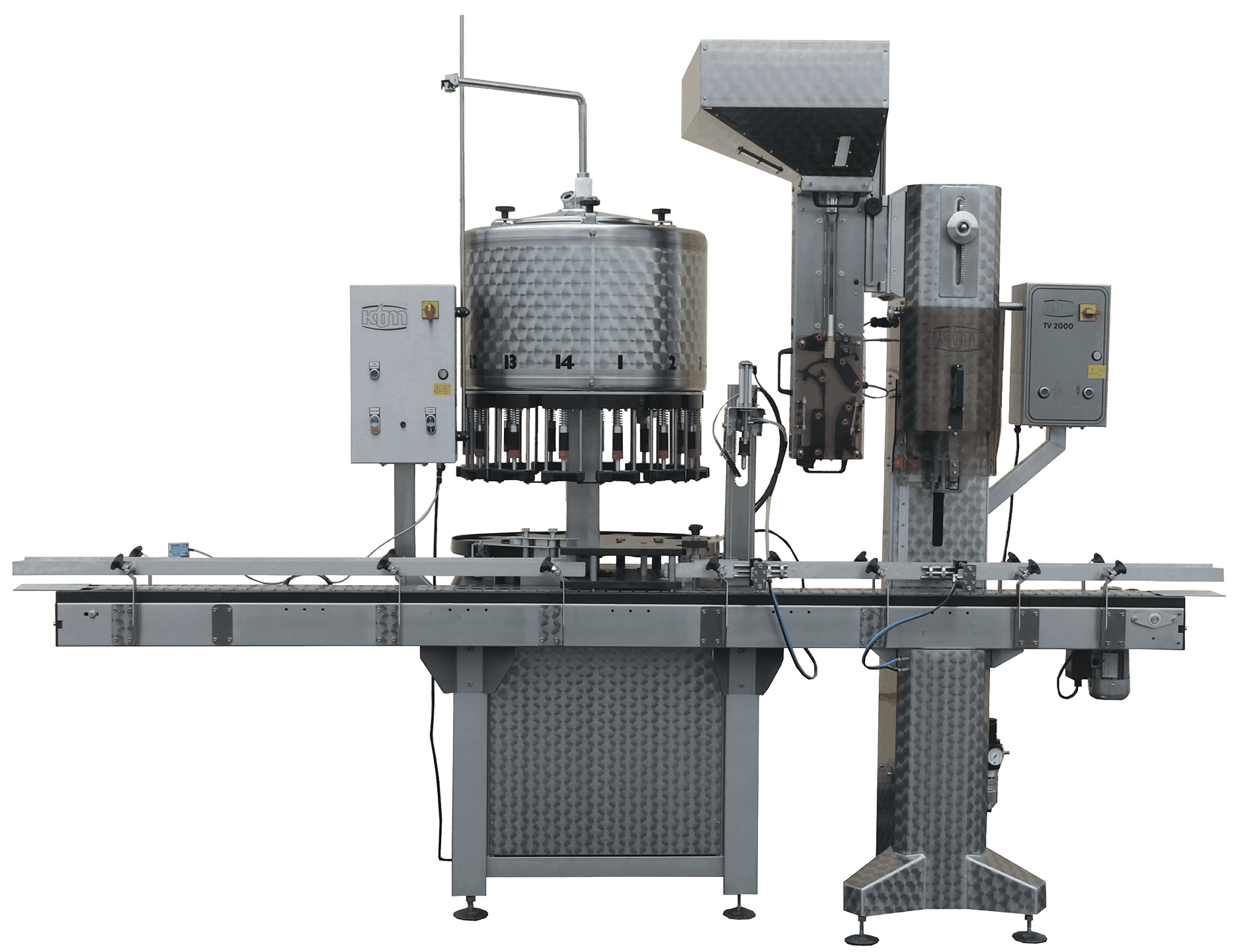

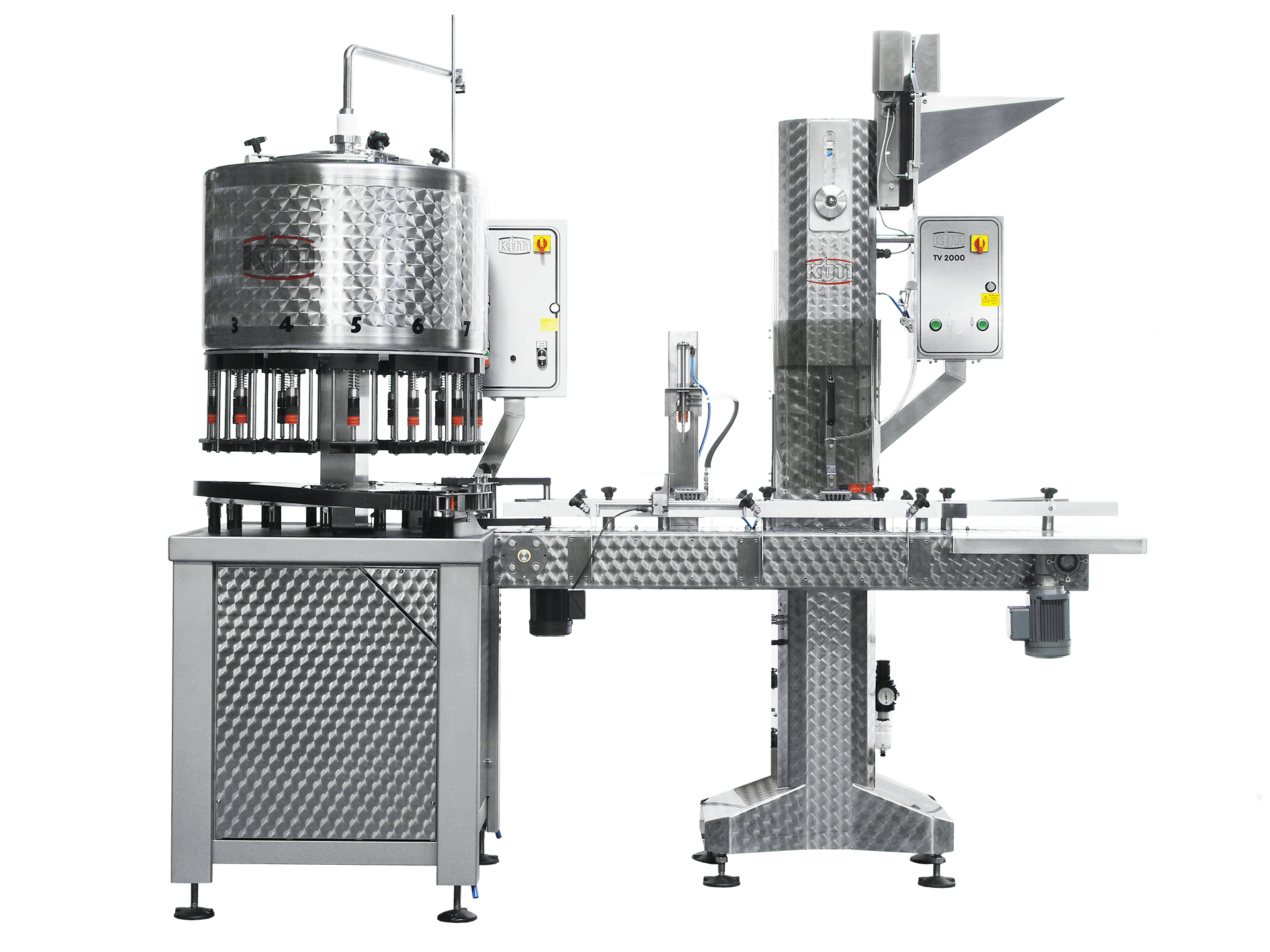

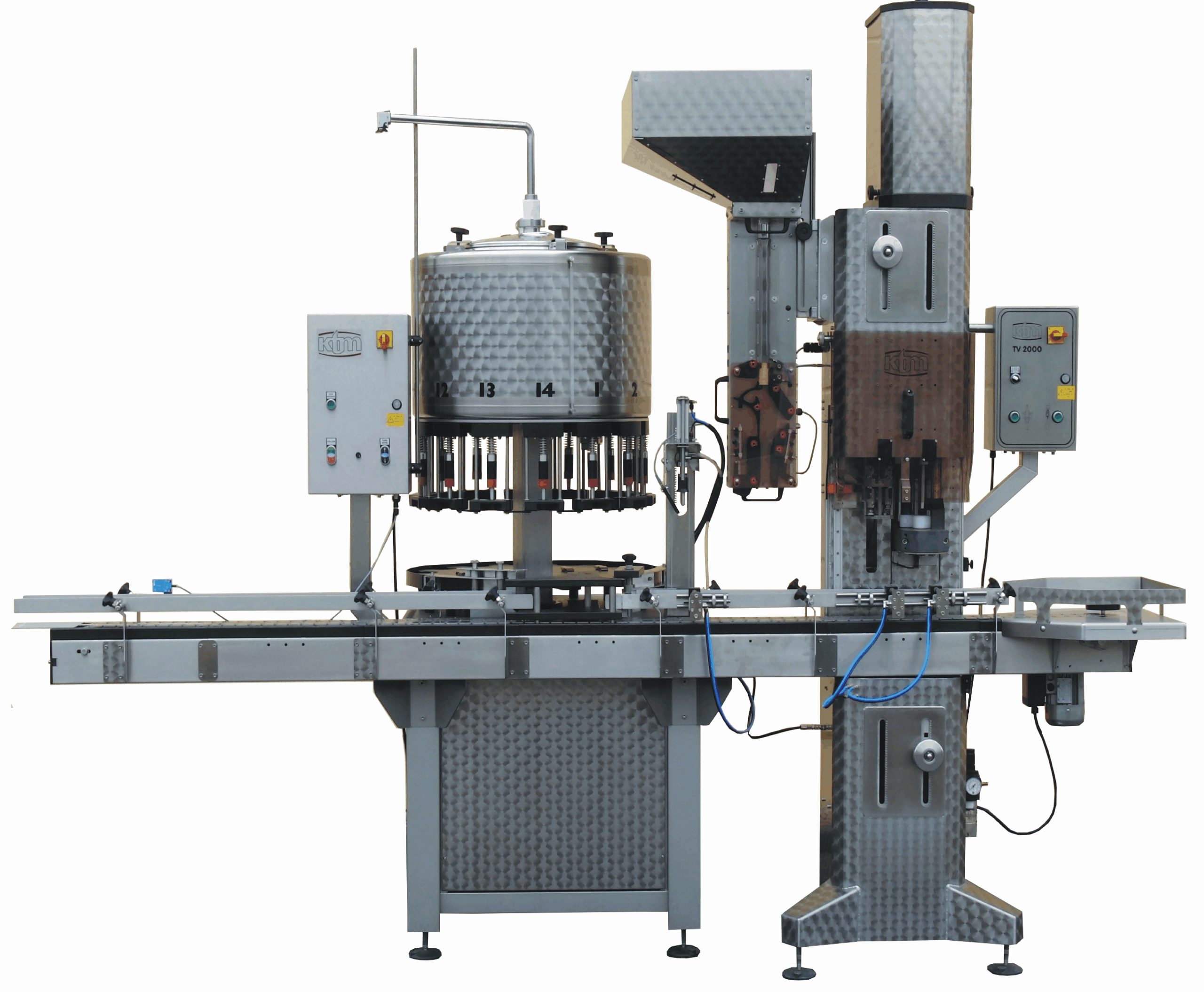

Bottle filling and capping machine TVA

The perfect combination - KTM bottle filler and capper for all cap types

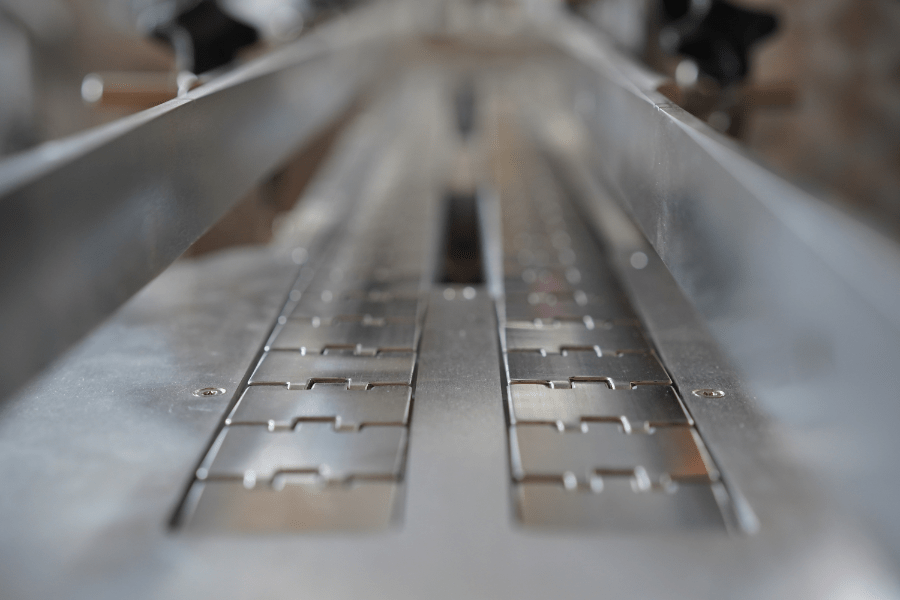

round drop pressure filler with 10, 14 or 16 stations

with one or two capping stations for all cap types (ShortCaps, LongCaps, natural corks, crown caps, twist-off, etc.)

electric tank height adjustment to easily fit different bottle heights and fill levels

easily replaceable starwheel for different bottle diameters

electronically controllable filling output

capper does not have format parts, which makes it easy to adjust the bottle diameter and height

uses high-quality industrial capping heads with pneumatic cylinder for professional capping

faster and less complicated to assemble and disassemble

variant for hot juices available

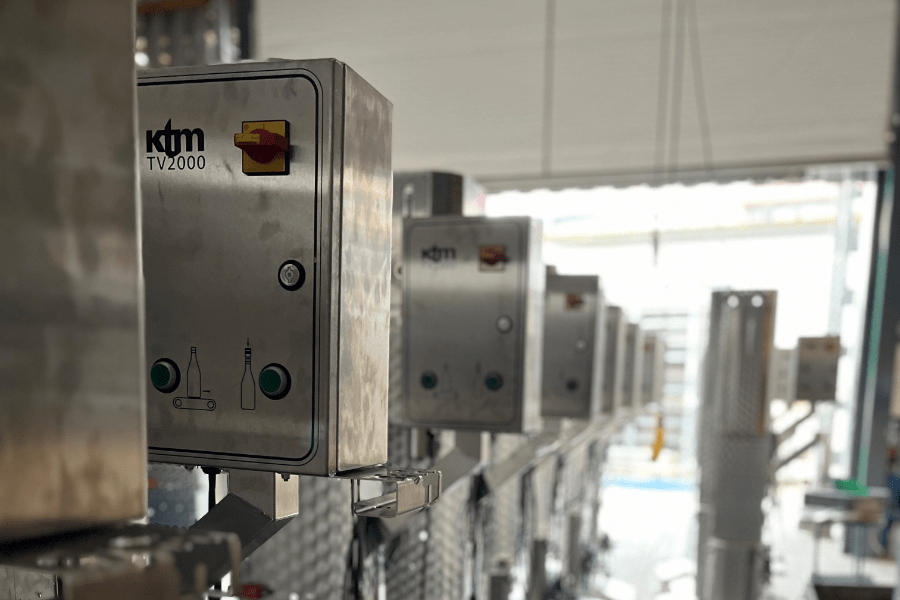

Standard versions

TVA2010

with 10 filling stations

TVA2014

with 14 filling stations

TVA2016

with 16 filling stations

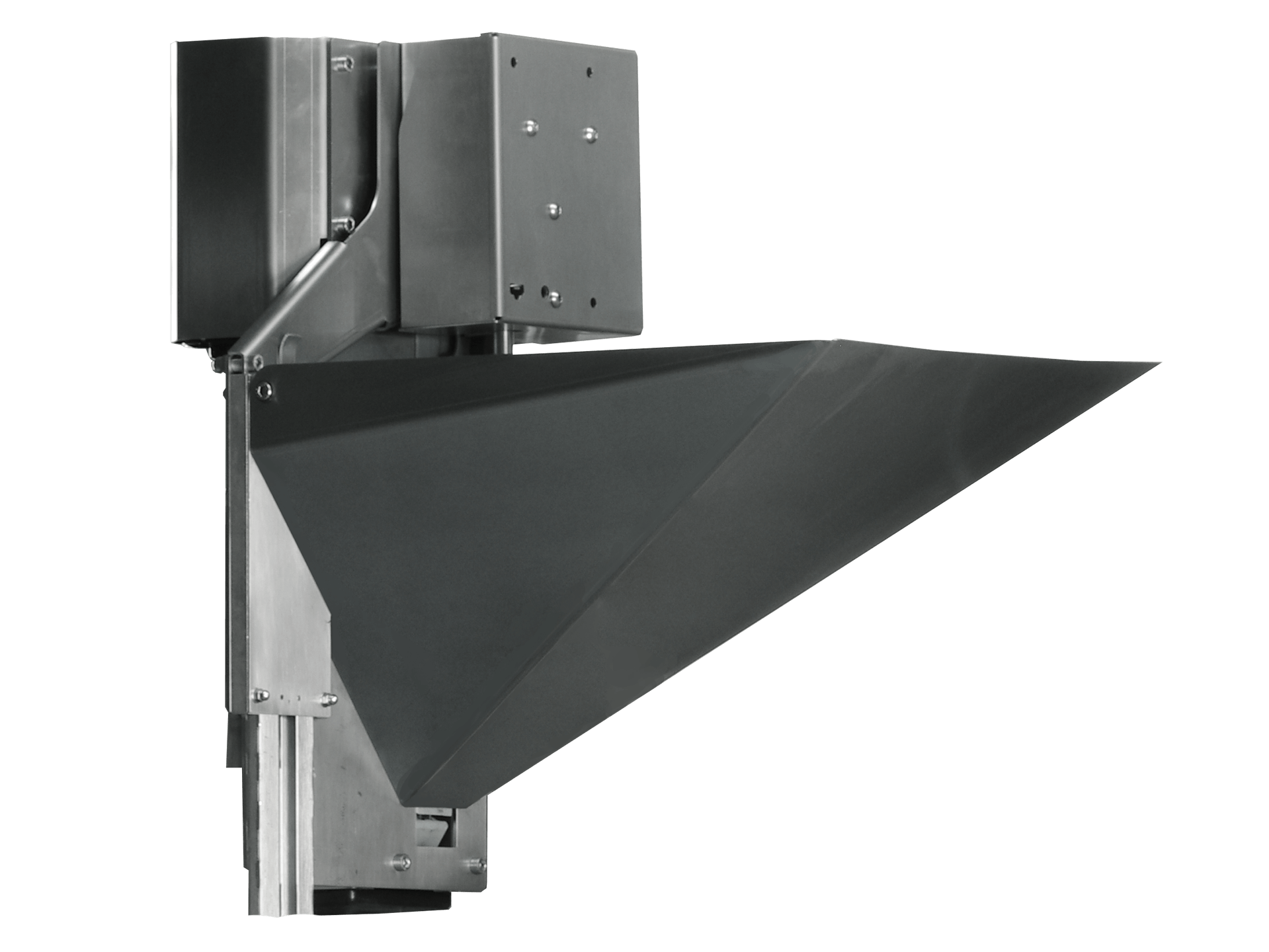

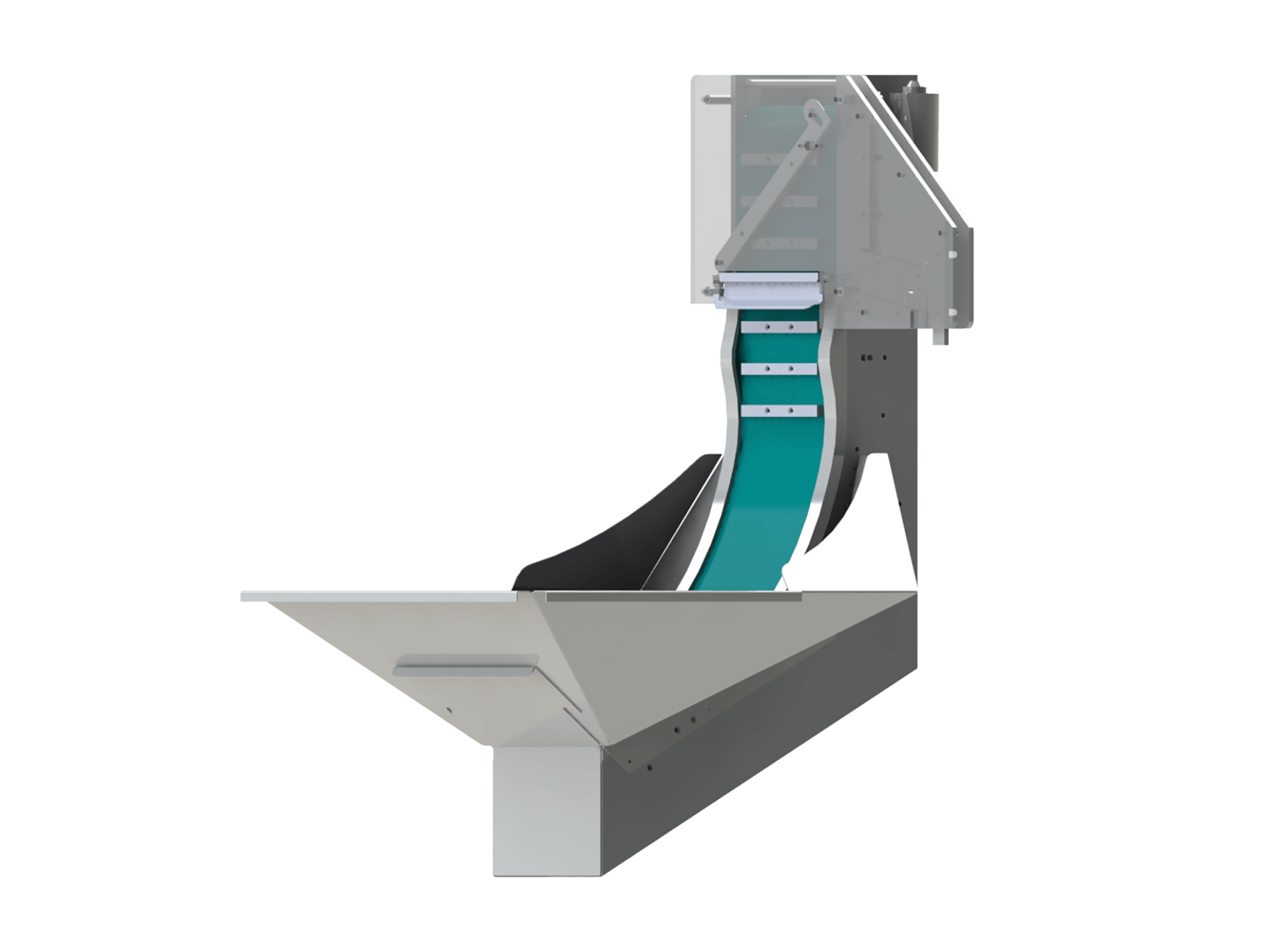

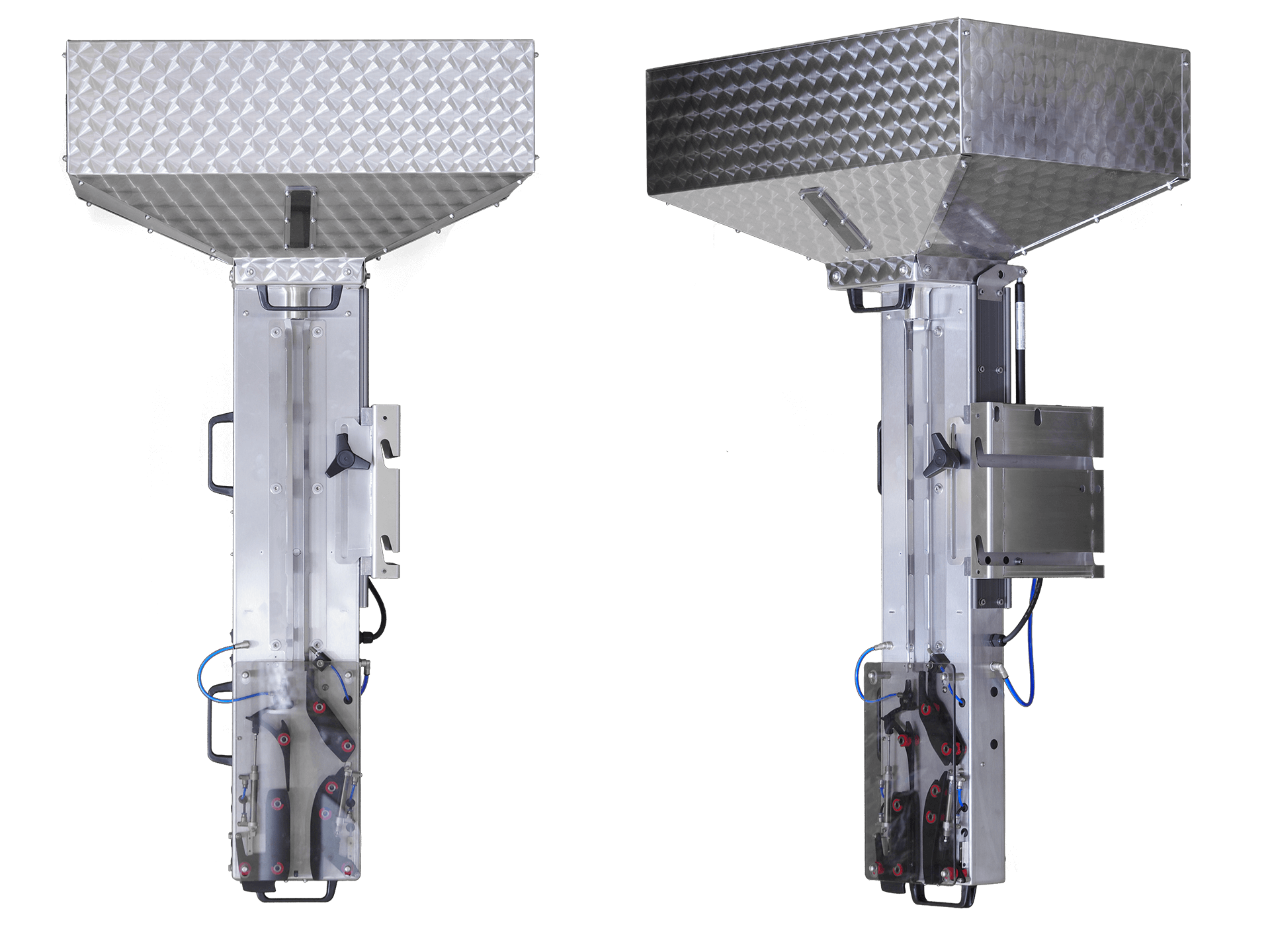

Sorting and placing units:

Depending on the type of closure required, the appropriate fully automatic sorting and fitting unit is included in the scope of delivery:

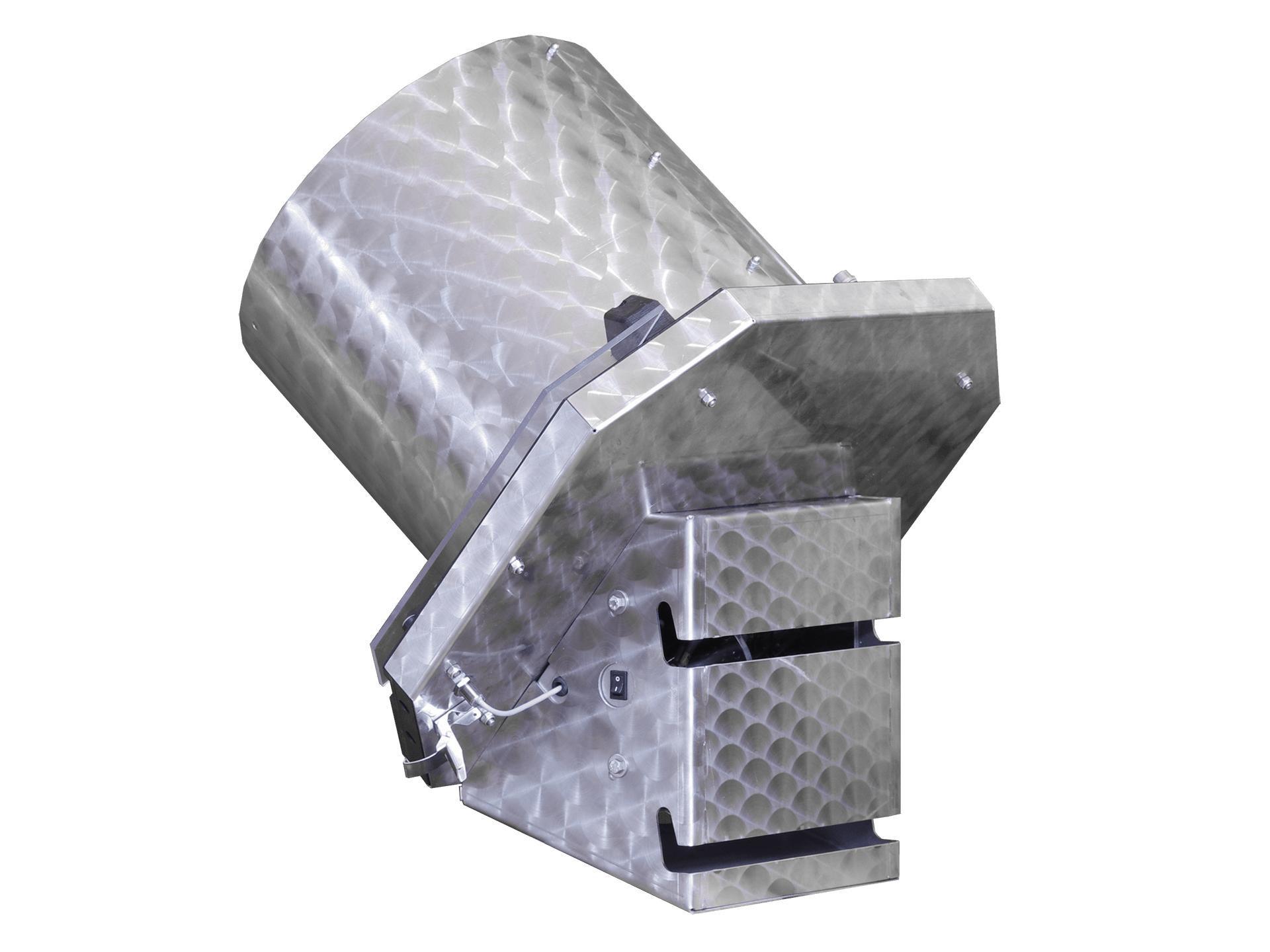

Sorter TSL (LongCap)

Sorting and placing unit for LongCaps Accurate feeding, capping and stocking of the caps in one device

See in detailTechnical data

Electrical connection

230V AC

Dimensions (L x W x H) [mm]

3000 x 1050 x 2250 (2500 x 900 x 2250 Compact)

Weight [kg]

400 / 450

Filling valves

10 / 14 / 16

Container volume [l]

90 / 200 / 200

Capacity up to [bottles/h]

1600 / 2000 / 2200

Bottle height [mm] max.

180-380

Bottle diameter [mm]

55-90

Optional extras