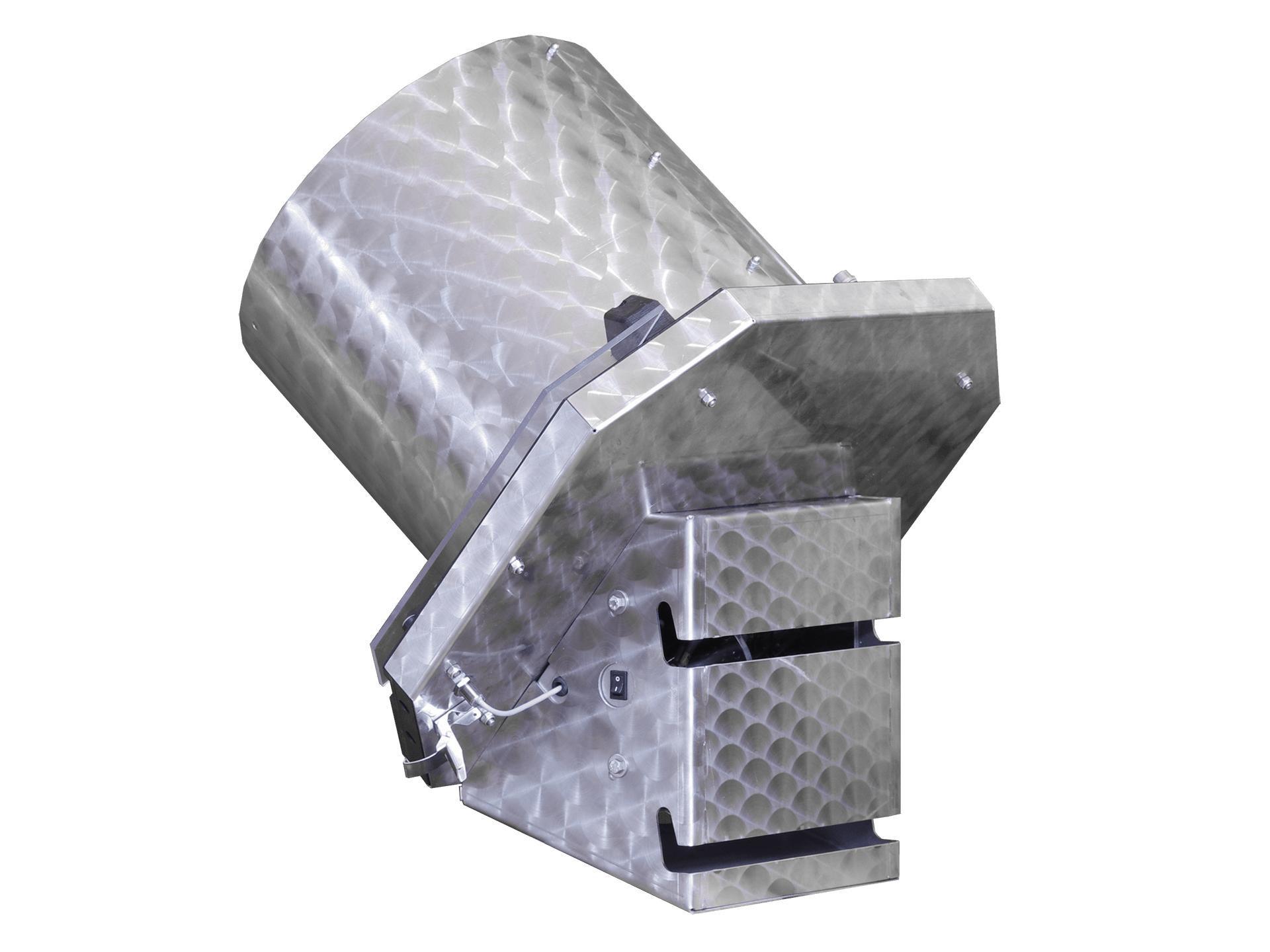

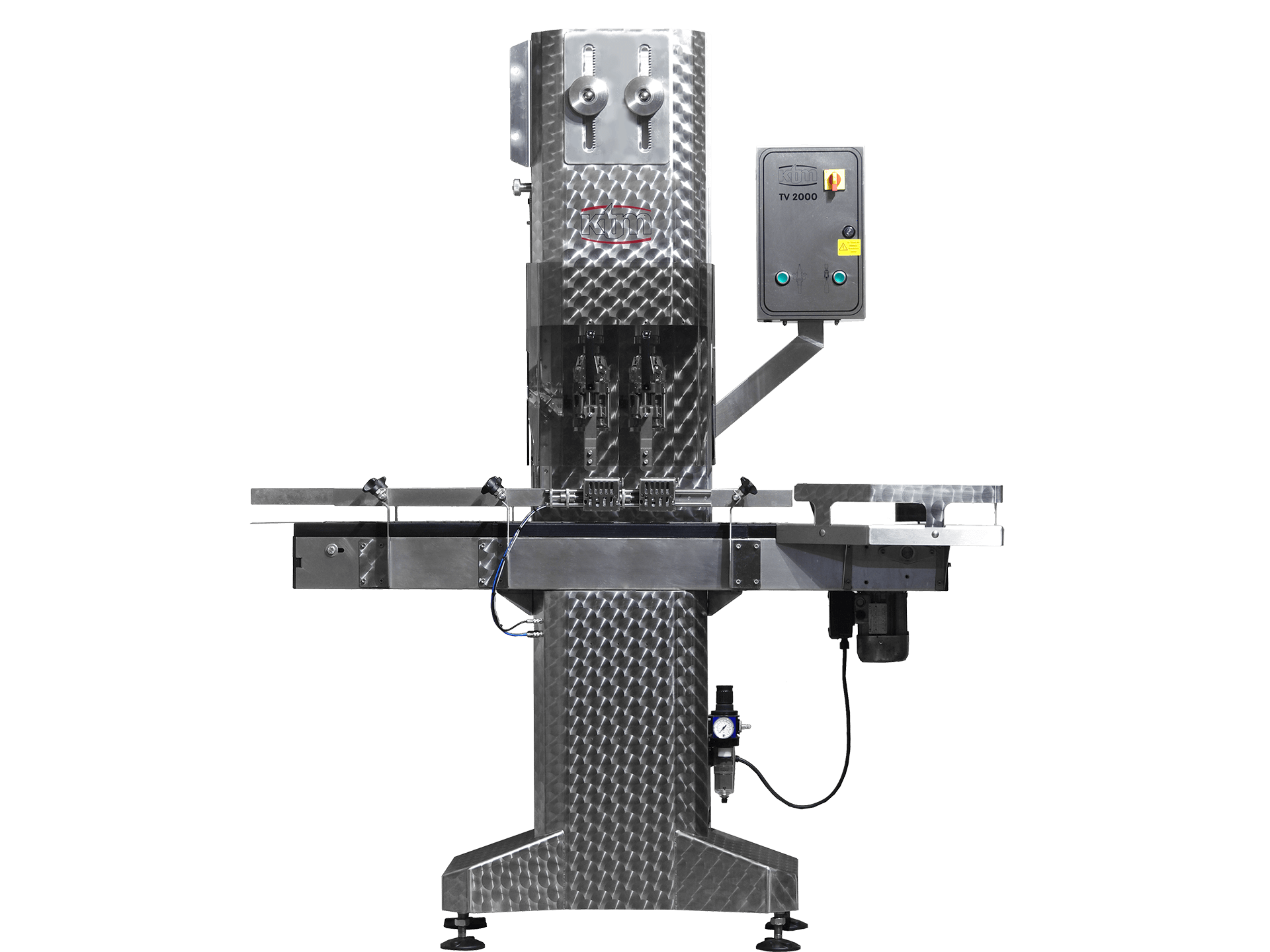

Fully automatic capper TV2000 Twin

Combination machine with two ready-to-use capping stations - meaning no time is needed to convert from one cap type to another

two single-head capping units for up to 2500 bottles per hour

easy to adjust bottle diameter and bottle height without format parts

manual cap feed possible

compact design

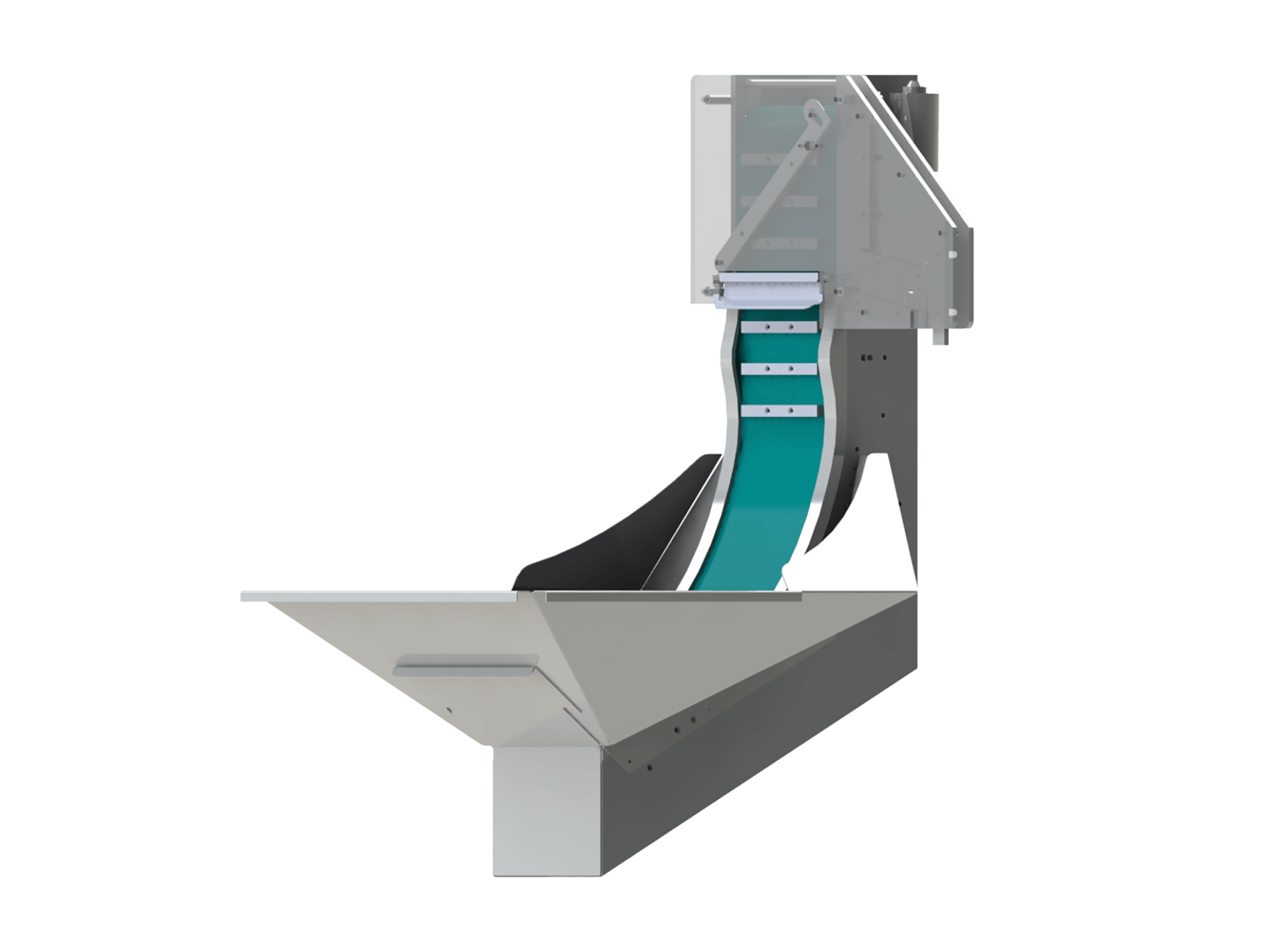

simple integration into existing filling line

uses high-quality industrial capping heads with pneumatic cylinder for professional capping

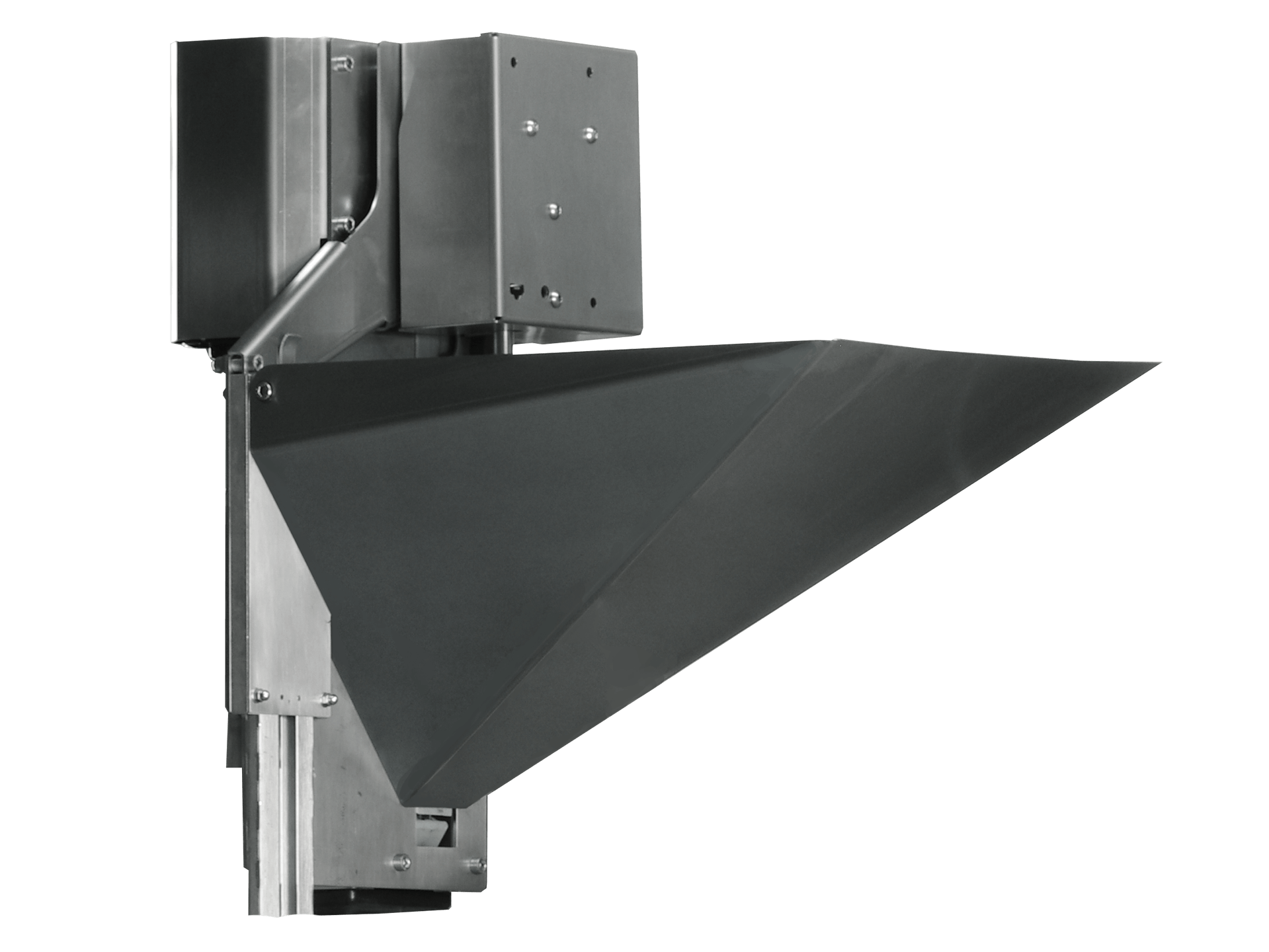

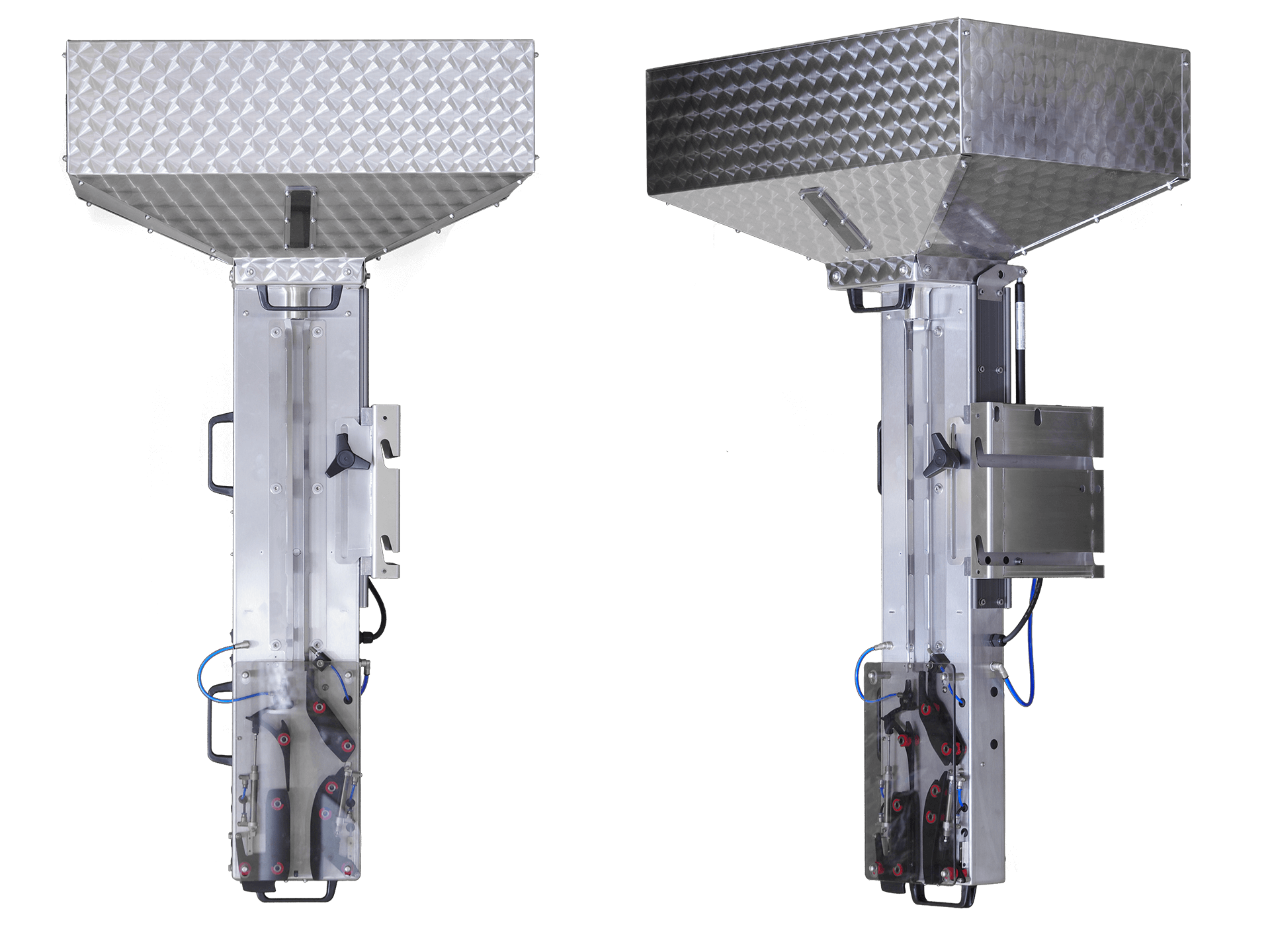

a faster and less complicated way of assembling and dismantling the belt and sorting unit

machine is well suited to mobile usage (e.g. contract bottling operations)

made entirely from stainless steel for a long service life and ease of cleaning

quick change bracket for sorter

a good addition to the KTM bottle fillers TA10/14/16

Standard versions

TV2000LX

With the TWIN machine, it is also possible to close long screw caps with internal threads internal thread (Stelvin-Lux, WAK, etc.).

TV2000LC

For LongCap / long screw caps (Stelvin / BVS 30x60, etc.) and for crown corks (Ø26, Ø29 etc.)

TV2000LK

For LongCap / long screw caps (Stelvin / BVS 30x60, etc.) and natural corks

TV2000SC

For ShortCap / short screw caps (MCA, PP28, etc.) and for crown caps (Ø26, Ø29 etc.)

TV2000SK

For ShortCap / short screw caps (MCA, PP28, etc.) and for natural corks

Sorting and placing units:

Depending on the type of closure required, the appropriate fully automatic sorting and fitting unit is included in the scope of delivery:

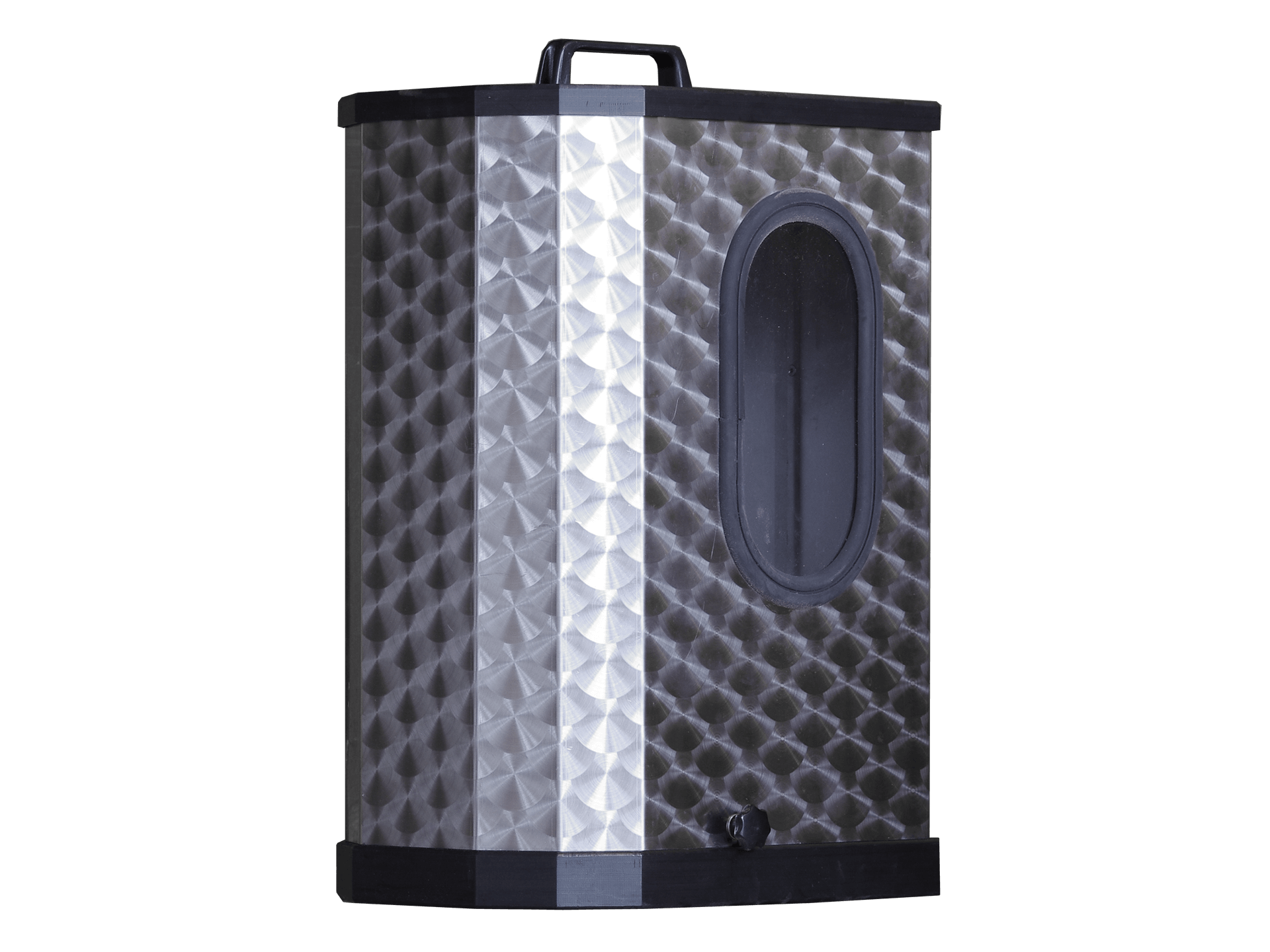

Sorter TSL (LongCap)

Sorting and placing unit for LongCaps Accurate feeding, capping and stocking of the caps in one device

See in detail

All sorting and placing units can be attached to the TV2000TWIN using a quick-change procedure. The 24 VDC supply voltage and compressed air (only for TSL) are obtained directly from the TV2000TWIN. This makes it possible to convert a TV2000S to a TV2000L or vice versa in a very short time. Only a second sorting applicator and a second capping head are required.

Technical data

Electrical connection

230V AC

Dimensions (L x W x H) [mm]

500 x 900 x 2000

Weight [kg]

250

Noise level [dB(A)]

<85

Effective air requirement [l/min]

200

Inlet pressure [bar]

6

Capacity up to [bottles/h]

2500

Bottle height [mm]

180 - 390

Max. Bottle diameter [mm]

90

Optional extras